Inspection of the Galvanizing Cleaning and Coating Process

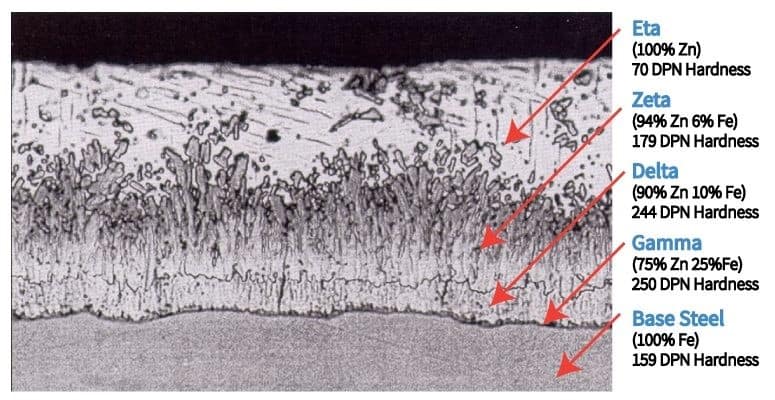

Introduction – Hot dip galvanizing is cleaned and painted for both beautification and protection. This coated galvanizing system is commonly called a Duplex System. In order for coatings to adhere and provide the desired service life, the quality of surface preparation and coating application must be assured. This can be accomplished by thoroughly inspecting each […]

Inspection of the Galvanizing Cleaning and Coating Process Read More »