KTA UNIVERSITY

Let’s Talk About Surface Soluble Salt Remediation Practices

April 16, 2024

In this article, we address soluble salt thresholds, offer options for remediating surface soluble salt concentrations, and describe how salt contamination may be removed from ...

Read More →

Let’s Talk About Removing Flash Rust Without Re-Blasting

March 12, 2024

This article describes how flash rust can be removed from abrasive blast cleaned steel surfaces without having to incur material and labor costs associated with ...

Read More →

Let’s Talk About Preserving the Blast Using Passivators

February 15, 2024

KTA’s Certified Coating Inspector Forum Volume 3, Issue No. 2 – February 2024 William Corbett, COO AMPP Senior Certified Coating Inspector & Certified Protective Coating Specialist ...

Read More →

Let’s Talk About Inspection Planning

January 15, 2024

A properly prepared Inspection Test Plan can provide a roadmap of what to inspect, how to inspect, and what the acceptance criteria are, while minimizing ...

Read More →

Certified Coating Inspector Forum: Volume 2

January 4, 2024

This 2nd volume of the Certified Coating Inspector Forum is a compilation of 12 articles to help you stay up-to-date in the coatings industry.

Read More →

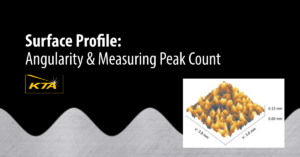

Let’s Talk About Surface Profile: Understanding Angularity and Measuring Peak Count/Density Using Stylus Instruments and Optical Grade Replica Tape

December 11, 2023

Discover the nuances of surface profile including angularity and peak density using stylus instruments & optical tape.

Read More →

Let’s Talk About Holiday Detection and Why Voltage Matters

November 6, 2023

Learn about the four W’s of Holiday/Pinhole Detection (What, When, Where, and Why), performing low and high voltage holiday detection, the steps that should be ...

Read More →

KTA-Tator, Inc. Plays Integral Role in Enhancing Safety for Mountain Valley Pipeline (MVP)

October 23, 2023

KTA is providing independent, third-party pipeline coating inspection services for the Mountain Valley Pipeline project.

Read More →

Let’s Talk About the Role of a Coating Inspector During a Failure Investigation

October 10, 2023

Inspectors hope to never have to participate in a failure investigation or dispute resolution. But if you do, it's important to be prepared.

Read More →