Introduction – A number of different coating systems can be applied to galvanizing for both beautification and protection. When galvanizing is coated, the longevity of the corrosion protection system is greater than the sum of the longevity of the galvanizing alone and the coating system alone. A system that consists of coated galvanizing is generally known in the industry as a duplex system. A number of different coatings can be applied to galvanizing depending on the service environment and the importance of aesthetics.

Coating Systems for Galvanizing – The selection of a protective coating system to be applied over hot dip galvanizing is dependent on several factors. The Society for Protective Coatings issued Technology Guide Number 19, “Selection of Protective Coatings for Use over Galvanized Substrate.” The guide explains that galvanizing may be overcoated to protect it from certain service environments to which it has marginal or poor resistance, or it may be top coated for aesthetics purposes. Some of the service environments that can be problematic for bare uncoated galvanizing are:

Atmospheric chemical exposure with environments that expose galvanizing to a pH of less than four or greater than 10.

Buried or immersed conditions were the galvanizing is in almost constant contact with water where a relatively rapid depletion of the zinc can occur.

Marine environments where the galvanizing is subject to high levels of humidity and salts.

The types of coatings that are typically used on galvanized steel are similar to the types of coatings used on other metallic surfaces. This article is intended to be a general guideline, recognizing that not all suitable coatings are addressed.

The longevity of the coating system depends on several factors. One of the most important is the barrier properties of the coating. The barrier properties of the coating are its ability to resist the transfer of moisture and oxygen through the coating. In a duplex system the coating applied over the galvanizing is the first line of defense.

There are additional considerations when coating galvanizing that may not be necessary on bare steel surfaces. One is the nature of the zinc corrosion product. Zinc corrosion products are alkaline so coatings that have poor resistance to alkaline surfaces, such as alkyd coatings, should not be applied to galvanizing unless specifically recommended by the manufacturer. Additionally, coatings that require a deep surface profile to gain adequate adhesion should generally be avoided, since the creation of a deep profile will remove too much of the galvanizing itself.

It should be noted that there are several post galvanizing treatments that may be performed by the galvanizer that are detrimental to the application of coatings. They are discussed in Topic 4 (surface preparation) of this series, but the most common post treatments that can impact coating adhesion are water quenching and chromate quenching. It is advisable to contact the galvanizer to let them know that the galvanized steel is going to be coated so that adverse post treatments can be avoided. But not all post treatments are detrimental to coating adhesion. Zinc phosphate will enhance adhesion and acrylic passivation treatments are appropriate for certain coatings.

There are thousands of different formulations of the various generic coating types. Before a coating is selected for application for galvanizing, the manufacturer should be consulted to confirm the compatibility of the coating with galvanized steel and any post treatment that may be present. Some coatings that are typically applied to galvanizing are:

Zinc Coatings

There are several types of zinc coatings that can be applied over galvanizing but zinc coatings are typically used only to repair damaged areas on the galvanizing, not as a continuous coat. Zinc coatings are liquid applied coatings containing zinc powder that is held together by a binder. Organic zinc rich primer can be used as a repair coating for galvanizing in most situations. There are several different types of binders that can be used but the most common is epoxy followed by moisture cure urethane. Organic zinc rich primer can be used on surfaces that are not expected to be subjected to temperatures over 300°F. At higher temperatures (up to 750°F) inorganic zinc rich coatings can be used. These coatings typically have an ethyl silicate binder. During the curing process the coating releases ethyl alcohol and the resultant binder matrix has no organic functionality, which gives it excellent temperature resistance. The temperature resistance of inorganic zinc rich coatings is limited by the melting point of metallic zinc. The inorganic zinc primer requires that the surface be abrasive blast cleaned. Organic zinc primers are also best applied over blast cleaned steel, but are capable of performing over a thorough power tool cleaned surface.

There are also zinc containing primers available in spray cans. These products are often used to touchup defects that form during the galvanizing process or after welding. The products consist of zinc powder in a solution of resin, solvents, and propellants.

If the zinc coatings are untopcoated and exposed outdoors, the inorganic zinc will exhibit white zinc salts over time and the epoxy zinc with chalk and discolor. The moisture cure urethane will yellow. The zinc in a spray can will typically resist yellowing or chalking, but the corrosion protection is generally not as great.

Wash Primers

Wash primers can be applied to galvanized steel to increase the adhesion of the coating system. Wash primers are typically based on a polyvinyl butyral resin and contain an etching solution, usually phosphoric acid. The etching solution neutralizes the alkaline surface oxides and hydroxides and etches the surface of the galvanizing, increasing the adhesion. Wash primers must be topcoated and it is important to select a coating system that is compatible with the wash primer. Wash primers should not be used on galvanized surfaces that have been chromate quenched or have received a phosphate post treatment. While wash primers provide an excellent base for coatings, they may not meet restrictions on VOC.

Acrylic Systems

There are several coating systems that are based on aqueous dispersions of acrylic resins that are appropriate for application over galvanized steel surfaces. There are advantages and disadvantages of acrylic dispersions. Since they are a water-based coating, they have a very small percentage of VOCs or none at all. Advances have been made in the formulation of aqueous acrylic dispersions but in general the still have a higher moisture permeability rate than most of the common solvent borne coatings. The acrylic dispersion coatings are not recommended for application to surfaces that are going to be exposed to severe environments such as marine or chemical exposure, but are appropriate for normal atmospheric exposure and interior applications. They also retain their color and gloss under ultraviolet light exposure.

Two Component Epoxy Coatings

Two component epoxy coatings have a reasonably low moisture permeation rate and can be formulated to be tough, hard and resistant to alkaline surfaces. They also generally have good adhesion to properly prepared galvanizing. As such, epoxy coatings are known to perform quite well when used in a duplex system as they have good resistance to water, chemicals, and pH variations and as a result can be used in a relatively harsh environments including immersion.

Although they have numerous beneficial properties, two component epoxy coatings have poor resistance to ultraviolet light making them a particularly poor choice for exterior exposure unless they are top coated to protect epoxy from sunlight. With no topcoat, the epoxy coating chalks and in extreme cases erodes. Once the epoxy coating has fully cured it can be difficult to successively topcoat because subsequently applied coatings may not properly adhere to the surface of the epoxy without first roughening the surface.

There are several different topcoats that can be applied to the epoxy coating that provide UV protection. One of the most common is polyurethane. The polyurethane coating has good resistance to moisture permeation and good gloss retention. Polysiloxane coatings are also known to have excellent gloss retention and perform well upon exterior exposure even in relatively harsh environments. Fluoropolymer topcoats are relatively expensive but have superior gloss resistance and have been known to retain their gloss for decades.

Powder Coatings

Powder coating is applied to a surface as a dry powder, usually by electrostatic spray. The material is then heat cured. It has several advantages over liquid applied coatings. Since the material is applied as a dry powder it contains no VOCs and as such is environmentally friendly. It generally provides a more uniform, consistent film as compared to liquid applied coatings. It also produces a finish that has excellent surface hardness and wear resistance. On the other hand, powder coatings have some limitations. Powder coating is a shop process and there are limitations to the size pieces that can be powder coating since heat curing of the powder necessitates that the piece be put into a curing oven. The cost of setting up a powder coating process, including the purchase of necessary equipment, is higher than for liquid applied coatings.

The coatings can be either thermosetting or thermoplastic, but thermosetting powder coating is most commonly used on galvanizing. Although there are several different generic types of powder coating, the most common are based either on epoxy or polyester. Epoxy powder coats have some of the same advantages as the liquid applied epoxy coatings. This includes excellent resistance to water, chemicals and hydrocarbons. It also shares the same disadvantage: poor resistance to ultraviolet light. The polyester powder coatings have somewhat reduced resistance to chemicals, water and hydrocarbons but they have good ultraviolet light resistance making them particularly suitable for exterior exposures. Powder coatings can be applied in several layers using the same heat cure, so it is possible to apply an epoxy powder as a primer and topcoat it with a polyester powder, giving the system some of the benefits of both materials.

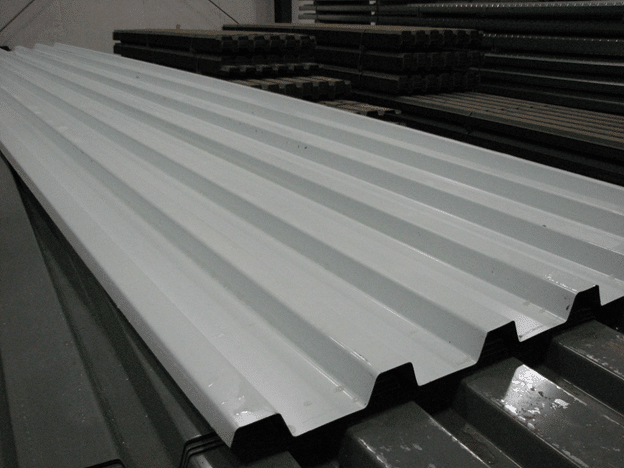

Coil Coating

Coil coating is a continuous automated process where spools of sheet-metal are coated. The process involves loading the spool of sheet-metal on one side of the line, unrolling it through a wash and pretreatment, priming the metal, curing the primer in an oven, applying the topcoat, and curing the topcoat in an oven. The metal is rolled back into a spool when it gets to the end of the line.

There is a wide variety of coatings that can be used in the coil coating process, but the commonly encountered coatings are polyester, plastisol, and PVDF. Polyester and plastisol have good exterior durability but the PVDF has excellent exterior durability and can retain gloss and color for several decades.

Conclusion – Different coating systems can be applied to galvanizing, both for beautification and for protection. The paints should be selected based on their ability to perform in the service environment. As the paint deteriorates, it can be touched up and replaced. With proper maintenance of the coating system, the galvanizing should never need to be replaced.

Other topics in this galvanizing series:

Topic 1 – Inspection of the galvanizing process

Topic 2 – Problems with galvanizing reactive steel

Topic 3 – Measurement of galvanizing thickness

Topic 4 – Preparation of galvanizing for painting

Topic 5 – Coatings for galvanizing

Topic 6 – Inspection of surface preparation and coating application