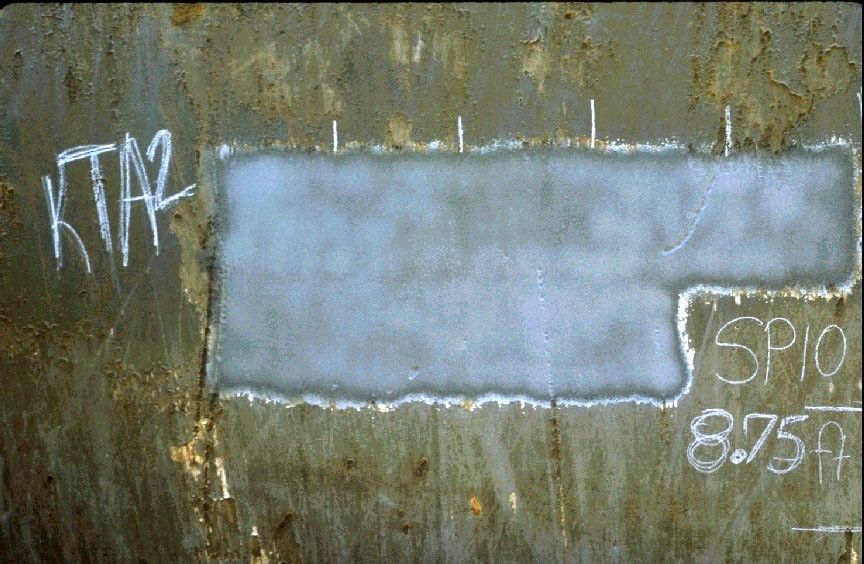

Let’s Talk About Using SSPC Visual Guide for Abrasive Blast Cleaning to Create a Project-Specific Cleanliness Standard

Learn about the proper use of the SSPC visual guide for abrasive blast cleaning and how it may be used to assist in creating a project-specific surface cleanliness standard.