Let’s Talk Instrument Calibration Vs. Accuracy Verification

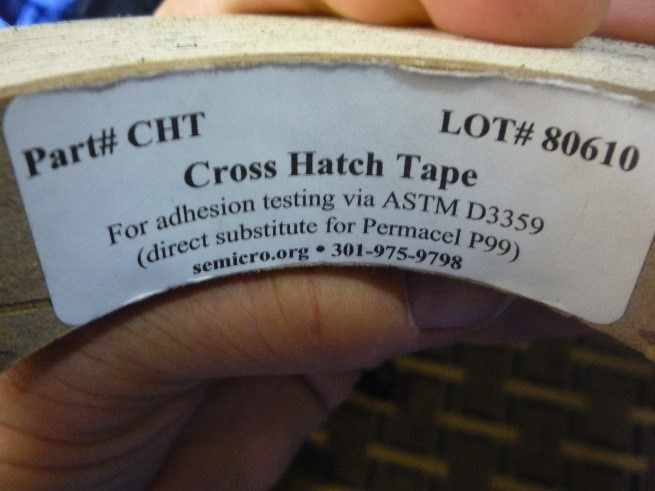

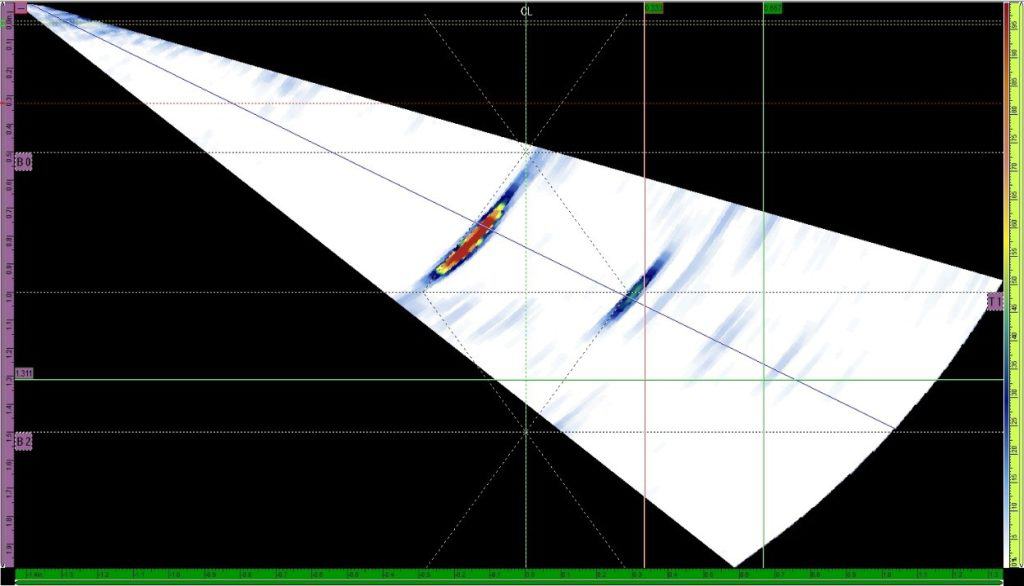

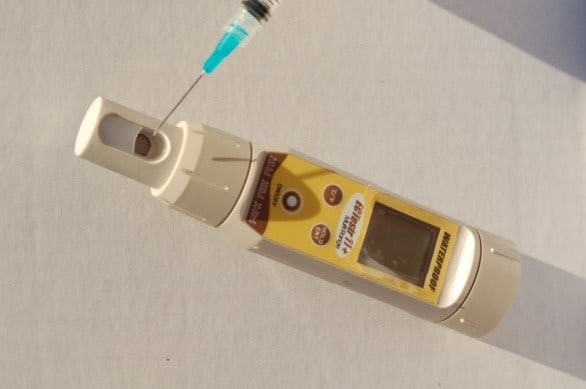

Instruments that are used to verify quality must be calibrated and verified for accuracy, when feasible. Instrumentation is calibrated by the equipment manufacturer or an accredited calibration laboratory, while the instrument user is responsible for verifying accuracy.

Let’s Talk Instrument Calibration Vs. Accuracy Verification Read More »