High Temperature, High Pressure, Depressurization Testing of Coating Systems Prior to Large Scale Installation

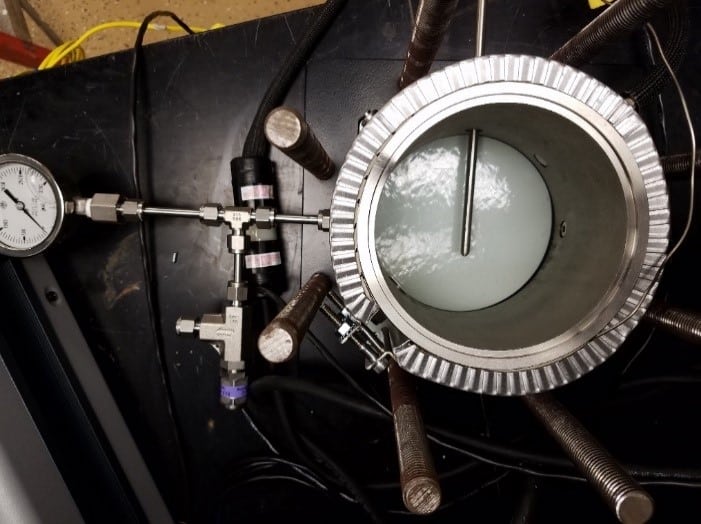

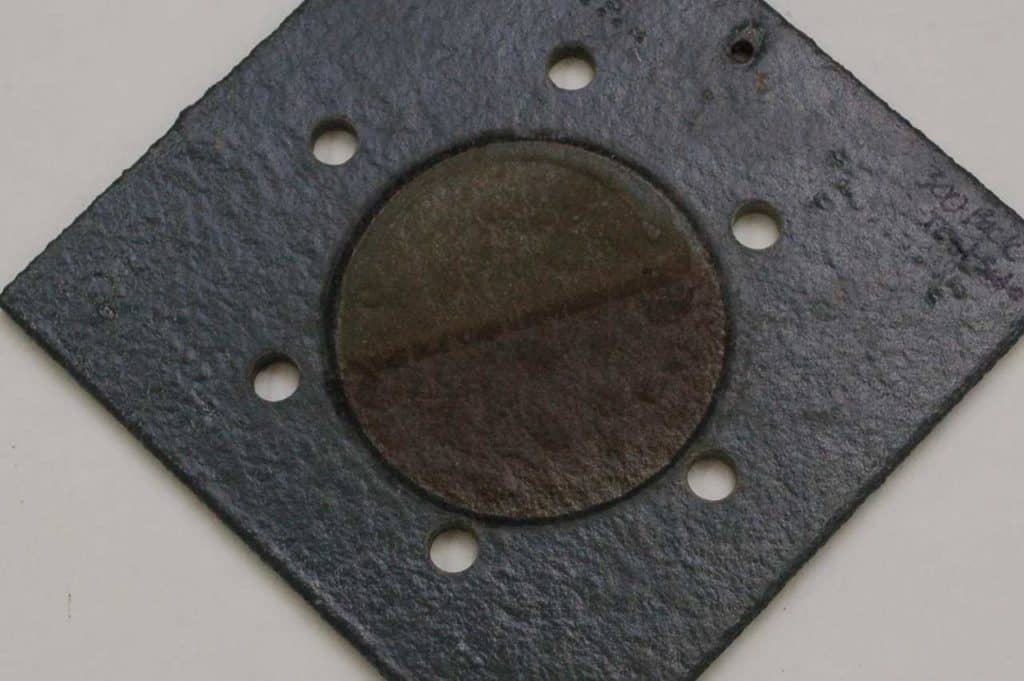

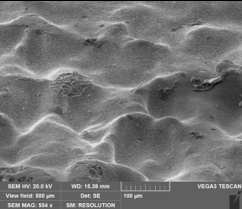

Introduction Industrial and marine protective coatings can provide decades of corrosion protection, provided the correct coating system is selected for the prevailing service environment, and that the coating system remains attached to the substrate it was designed to protect. Industrial coatings used in the water, wastewater, oil and gas, and nuclear power industries may be […]