Inspection of FRP Cleaning and Painting

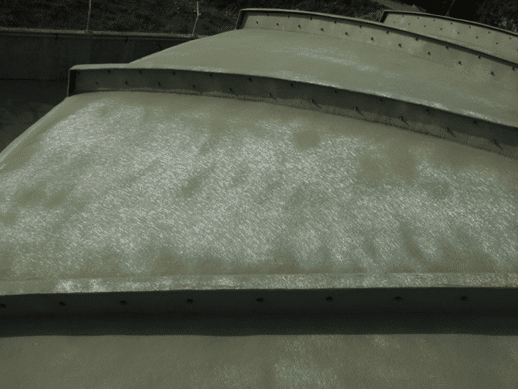

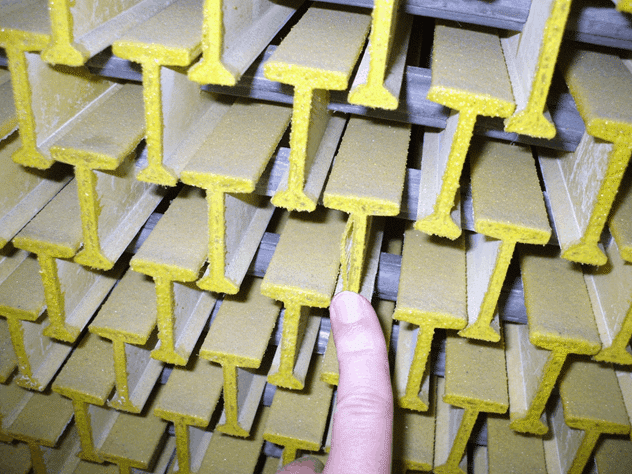

Introduction – Fiber Reinforced Plastic (FRP) surfaces undergo both chemical and physical aging during their useful life. Designers and manufacturers may specify that FRP surfaces be coated as a maintenance strategy to prolong its service life and/or improve its aesthetic qualities. A wide variety of generic coating types can be applied to FRP surfaces. For […]

Inspection of FRP Cleaning and Painting Read More »