Introduction – Fiber Reinforced Plastic (or polymer) is known as FRP. It may also be referred to as GRP (glass reinforced plastic), which is the same material. As the name for GRP suggests, glass fibers are used to provide the reinforcement, although carbon fibers are used for specific high-performance applications, such as structures requiring a high strength-to-weight ratio. When carbon fibers are used, it is known as CFRP or CRP for Carbon Fiber Reinforced Plastic (or polymer).

Components of the FRP Composite –Whether the composite is FRP, GRP, CFRP, or CRP it consists of two main components: a resin binder and glass or carbon reinforcing material (fiber).

Resin Binder – The resin binder provides chemical resistance to the service environment. General purpose components are typically made with a polyester resin. While they are generally less expensive than other resins, if chemical resistance is required, different resin(s) may need to be considered. For example, vinyl ester resins can be formulated to withstand a variety of chemical environments and are often found in chemical processing applications. Epoxy novolac resins can also be formulated for a variety of chemical exposures. Both vinyl ester and epoxy novolac resins have a higher material cost than polyesters. When carbon fibers are used, the resin is typically epoxy.

Reinforcing Material – The reinforcing material provides mechanical strength to the composite. Glass reinforcement comes in several forms. Chopped strand mat is a layer of randomly oriented glass fibers that provides equivalent mechanical strength properties in all directions. It is supplied in rolls or sheets and can be cut to size to fit the component being fabricated. Glass fibers can also be mixed into the resin using a chopper gun. The gun cuts and sprays the glass fibers onto the surface along with the resin. Another option is woven roving, which consists of strands of glass weaved together in a pattern similar to weaving a placemat or basket. This provides additional strength in the direction of the perpendicularly weaved fiber bundles, and can be used to provide additional strength where it is needed most. Unidirectional mat works similarly, except that nearly all of the fibers run in one direction. Long continuous strands are also used in the filament winding process (described below).

Methods of Fabrication – FRP can be fabricated using many different methods. A few are summarized below:

Filament Winding – Filament winding is common in the manufacturing of both tanks and piping. This is an automated process of applying the glass and resin to a spinning mandrel. The type of glass reinforcement, wind angle, and thickness can all be adjusted to meet the mechanical strength requirements. Diameter and length of the component is limited by the dimensions of the mandrel.

Hand Layup – Hand layup, open mold fabrication can be used to create parts in nearly any geometry. Layers of glass and resin are applied by hand (or chopper gun) to a mold of the desired shape. Each layer is rolled by hand to compact the laminate, uniformly distribute the resin, and remove air bubbles. This method is obviously more labor intensive than the automated methods, but it is also the simplest.

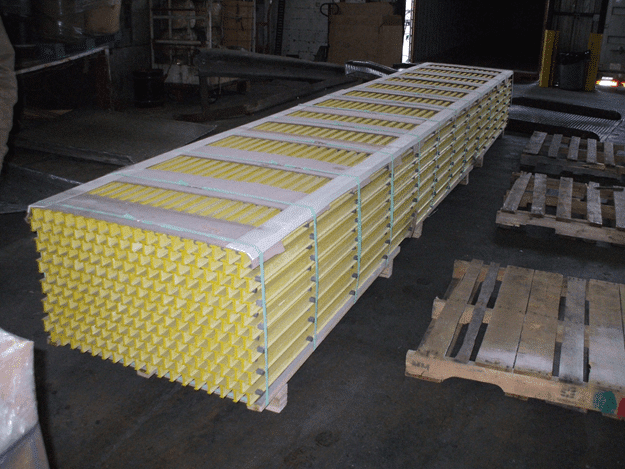

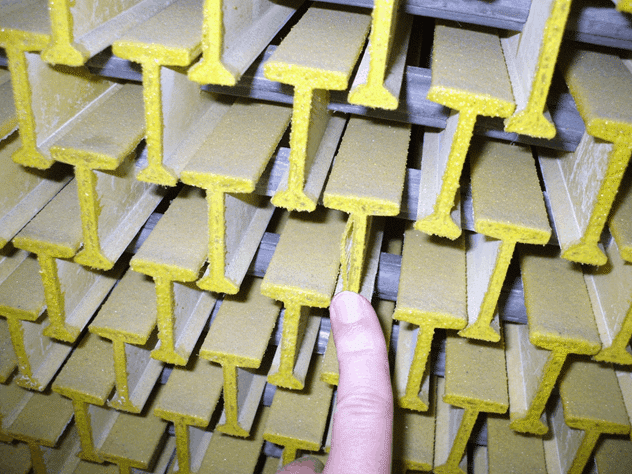

Pultrusion – Pultrusion works by pulling numerous single filament strands through a resin bath and then through a dye to form the desired shape. The shape of the dye determines the shape of the part and is most often heated to accelerate the curing process as material moves through it. This method is used to make I-beam, channel, tube, and other structural shapes. Once started, the process can run continuously with the desired lengths cut upon completion of the process.

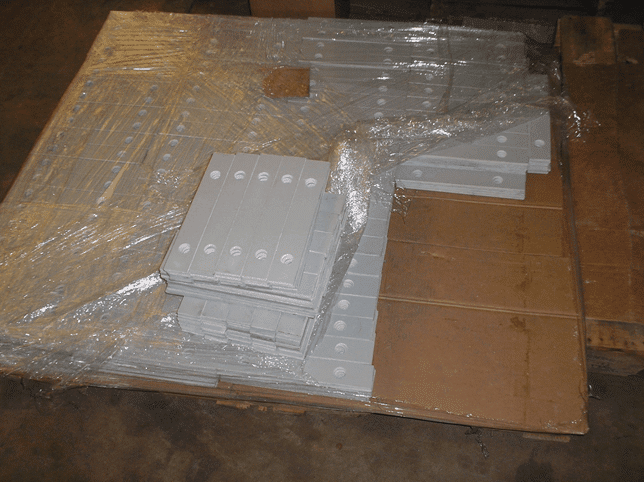

Compression Molding – Compression molding (closed molding) is an automated process that can fabricate complex shapes quickly. Pre-cut reinforcement is first inserted into one half of the mold. As the mold is close, resin is injected to fully wet out the reinforcement. High pressure is then applied to compact the laminate into the desired shape and force out any air bubbles. Again, heat is often applied to accelerate the curing process.

Inspection Steps – Once completed a laminate should undergo many quality checks.

ASTM D2563 Visual Inspections– ASTM D 2563, “The Standard Practice for Classifying Visual Defects in Glass-Reinforced Plastic Laminate Parts” provides a complete lists 28 defect types for inspection in Table 1, together with the size/number of defects allowed and photographic examples of the defects. The standard establishes three visual acceptance levels for the defects from Level 1 (no defects) to Level III (a few defects). The standard also allows for the development of product-specific limitations (Level IV), which would be specified on the product drawings.

The defects requiring a visual examination in Table 1 of the standard, and a brief description are as follows (Note: the ASTM standard should be reviewed for the detailed definitions and acceptance criteria for each of the Levels):

- Chip (broken piece at an edge or surface)

- Crack (through the full thickness)

- Crack (surface of laminate only)

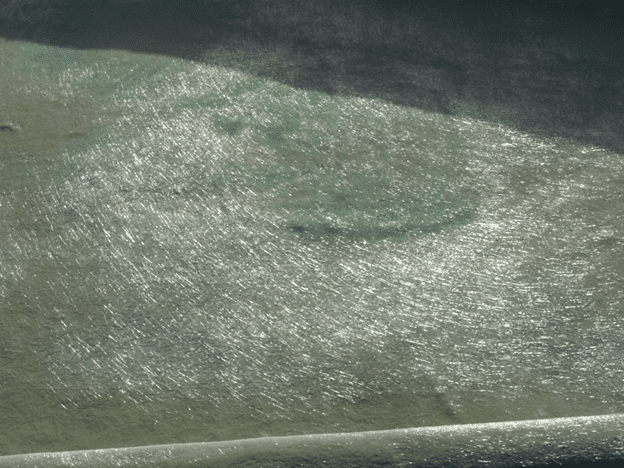

- Crazing (fine cracks under the surface of the laminate)

- Delamination (along an edge)

- Delamination (separation of layers within the laminate)

- Dry-spot (reinforcement not fully wetted)

- Foreign inclusion (metallic)

- Foreign inclusion (nonmetallic)

- Fracture (rupture of the laminate without complete penetration)

- Air bubble (void)

- Blister

- Burned (thermal decomposition)

- Fish-eye (small globular mass that has not blended into surrounding material)

- Lack of fillout (reinforcement not wetted)

- Orange peel (uneven texture resembling the surface of an orange)

- Pimple (small, sharp or conical elevation)

- Pit (pinhole)

- Pre-gel (unintentional extra layer of cured resin on part of the surface)

- Resin-pocket (excess resin in small area)

- Resin-rich edge (insufficient reinforcing at the edge)

- Shrink-mark (depression in the surface of a molded laminate)

- Wash (area where reinforcement moved during closure of the mold resulting in resin-rich areas)

- Wormhole (elongated air entrapment)

- Wrinkles (appearance of a wave molded into one of more piles of reinforcement material)

- Scratch (shallow mark, groove, furrow, or channel due to handling

- Short (incompletely filled out condition)

Degree of Cure – As the resin cures, crosslinking of the polymer chain changes it from a liquid to a solid. The resin must be fully cured to provide the desired strength and chemical resistance. The degree of cure is checked by the Barcol hardness test in accordance with ADTM D 2583, “Standard Test Method for Indentation Hardness of Rigid Plastics by Means of a Barcol Impressor.” The instrument is equipped with a spring-loaded cone (indentor). The relative depth of penetration of the indentor into the surface provides an indication of the material’s hardness, and thereby, the degree of cure. The product data sheets of the resin manufacturer will indicate the Barcol hardness values needed to insure full cure.

Solvent Wipe – A solvent wipe test can also be performed. Acetone is applied to the test surface with a clean rag and if the surface is tacky after 30 seconds, it has not fully cured.

Mechanical Properties (tensile, flexural strength, resin-to-glass ratio) – Testing of mechanical properties is destructive. requiring the removal of samples. On tanks, samples are typically taken from cutouts at manways or nozzles.

Tensile strength is tested in accordance with ASTM D 638, “Standard Test Method for Tensile Properties of Plastics.” This requires cutting a sample into a specific shape and pulling it apart using a laboratory tensile testing machine.

Flexural strength is tested in accordance with ASTM D 790, “Standard Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Insulating Materials.” In essence, a sample is placed on two supports and a load is applied to the middle to determine flexural properties.

Another factor that can impact both the mechanical properties and chemical resistance of a laminate is the ratio of resin to glass. A higher glass content provides greater mechanical strength while higher resin content provides increased chemical resistance. This ratio can be tested in accordance with ASTM D2584, “Standard Test Method for Ignition Loss of Cured Resins.” The required value is typically stated in the project specifications and is used in the design calculations for determining the required thickness.

Conclusion – FRP is a very versatile material that can be formulated to achieve a variety of strengths and chemical resistance. But in order to provide the service that is intended, the fabricated items need to be thoroughly inspected to identify flaws and defects described in this article that could compromise that life. In many applications, the fabricated items are then cleaned and painted to improve performance and aesthetics, as described in other topics of this FRP series.

Other topics in this FRP series:

Topic 1 – Inspection of the FRP fabrication process

Topic 2 – Surface Preparation and Coatings for FRP

Topic 3 – Inspection of FRP cleaning and painting