AS SEEN IN June 2019 JPCL Magazine

Isocyanates are reactive chemicals often used in foams, elastomers, fibers and polyurethane paints. Exposure to isocyanates has been reportedly linked to irritation of the mucous membranes of the eyes, gastrointestinal and respiratory tracts. More serious health effects include asthma and inflammation of the lungs. In the protective coatings industry, exposure to isocyanates may occur during the mixing or application of polyurethane paints. The word isocyanate on a product label or safety data sheet (SDS) might prompt the user/specifier to select an alternative coating such as a product labeled as green or environmentally friendly. In some cases, facility owners and/or contractors have reportedly been reluctant to specify or use polyurethane coatings, based upon the belief that coatings containing isocyanates have more stringent personal-protective-equipment (PPE) requirements than those for application of coatings that do not contain isocyanates. A study was conducted to investigate this belief and determine if recommended PPE requirements differ between polyurethane and non-isocyanate-containing coatings.

EVALUATION METHODS

The study included the evaluation of 22 coating systems, falling into six coating groups: polyurethanes (containing isocyanates), epoxies, zincs, polysiloxanes, alkyd products and acrylic products. For each of the 22 coating systems, seven products from at least three manufacturers were selected, for a total of 154 products.

Each product was evaluated according to its product/technical data sheet (PDS/TDS) and its SDS. The assessment of the PDS/TDS focused on the recommended application method (spray or brush/roller) and intended use(s), generally, industrial maintenance painting, concrete flooring and/or automotive refinishing.

The assessment of the SDSs focused on the PPE requirements of each product, and in turn, these PPE requirements focused on four categories: hand protection, skin/body protection, eye/face protection and respiratory protection. For each of the four categories of PPE, the requirements were classified into one of the following categories:

- PPE is not required (or not addressed).

- PPE use is dependent upon concentration of the hazardous components during use, the tasks performed, or the site-specific conditions, (i.e., use PPE, as appropriate).

- PPE is required (type may be specified or unspecified).

These PPE requirement categories are illustrated visually in Table 1.

Table 1: SDS PPE Requirements.

The PPE requirements (of the 154 products evaluated) falling into each category illustrated in Table 1 were tallied for each of the six coating groups. The PPE requirement with the largest number of products was identified as the predominant PPE requirement for that coating group. For example, if a coating group was composed of 28 products and 21 of them required eyewear, the eye/face requirement for this coating group would be listed in red (eyewear required).

PPE REQUIREMENTS NOT SPECIFIC TO APPLICATION TYPE

The predominant PPE requirement for each coating group is illustrated in Table 2. As shown, PPE requirements between polyurethanes and non-isocyanate-containing paints did not differ. Generally, PPE requirements across all six coating groups were classified as yellow (PPE use is dependent upon concentration of the hazardous components during use, the tasks performed or the site-specific conditions). Only eye/face protection was classified as red (required by the SDSs across all six coating groups).

In the few cases where differences in PPE requirements between coating groups were found, PPE requirements for the non-isocyanate-containing coatings were more stringent than the polyurethane coating requirements. Specifically, the alkyd products (hand, skin/body protection) and acrylic products (hand protection in half of the evaluated SDSs) required more stringent protection compared to the polyurethanes.

For all six coating groups, the use of eye/face protection was a consistent requirement, whereas, most product SDSs did not require a specific type of protective glove, clothing or respirator. Many SDSs indicated that the use of protective gloves, clothing or respirator be based on the findings of a risk assessment (RA), site-specific conditions or the performance of a specific task such as spray painting.

Although little variability was identified between coating groups, some did exist within the coating groups (i.e., between the 22 different coating systems) and most was identified for hand and clothing requirements (Table 2). Hand PPE requirements varied primarily between always required or dependent upon site-specific conditions. Among the 22 coating systems, 46% (71) of the SDSs required hand protection while for 53% (82) of the SDSs, the requirements were dependent upon the site-specific conditions and one SDS did not require any hand protection.

Table 2: Summary of General PPE Requirements (Not Specific to Application Type).

The greatest variability was found between clothing PPE requirements. The SDS for 55% (85) of the products required protective clothing, while for 37% (57) the requirements were dependent upon site-specific conditions, and for 8% (12) the SDS did not require protective clothing.

Respirator requirements varied the least out of the PPE requirements. Most respiratory requirements (88%) were vaguely dependent upon conditions (for example, instructing to use respiratory protection as appropriate). However, many SDSs did require respiratory protection under specific circumstances (for example, if concentrations of hazardous components are unknown, if applying the coating in a confined space or with insufficient ventilation). In the absence of any of these special circumstances, the majority of SDSs did not require respirator use for any of the 22 different coating systems.

SPRAY APPLICATION PPE REQUIREMENTS

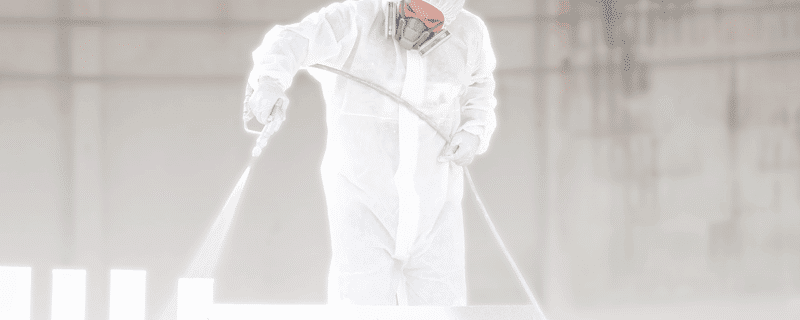

The same evaluation process was repeated for all products to identify specific PPE requirements during spray application. SDSs for 18% (27) of the evaluated products contained PPE requirements specific to spray application. For those 27 products, respirator protection was required during spray application. In addition to an increase in respiratory protection, one product specifically required additional clothing protection during spray application.

Though an increase in respirator requirements for spray application was noted for 27 products, there was no change to the overall classification of requirements between general respirator requirements (not specific to application type) and those specified during spray application—the PPE requirements between polyurethanes and non-isocyanate-containing paints did not differ even when the requirements were assessed by method of application.

DISCUSSION

The primary route of entry for toxins during coating application is via the respiratory system. Coating application tasks can result in inhalation exposure to vapors and mists during mixing, application and curing following application1. During spray-painting operations, workers are at a greater risk of inhalation exposure compared to brush/roller application. Therefore, although not required by the majority of SDSs, best painting practice suggests a respirator should be worn during spray application of the coatings assessed in this evaluation. The type of respirator selected should protect against the exposure levels of the hazardous components in each product, determined through personal air monitoring. This recommendation falls in line with the SSPC painting manual, Good Painting Practice recommendation to wear goggles and the proper respiratory protection when spray painting or performing any operation where an abnormal amount of vapor or dust is formed2.

When selecting a respirator, product users should consider the specific hazardous materials in the product along with the added effect of the hazardous components in the product being used concurrently. The use of respirators as the sole means of compliance is not recommended. The use of engineering controls must be evaluated and implemented before relying on PPE.

Components of each product were identified as hazardous if the following criteria were met:

Components were included in the SDS (per the OSHA Globally Harmonized System requirements);

Components were identified in the National Institute for Occupational Safety and Health Pocket Guide to Chemical Hazards (NPG) and;

Per the NPG, appropriate preventive measures to reduce or eliminate adverse health effects and accidental injuries were included.

Many of the hazardous components, such as organic solvents identified for each product, required all forms of PPE (eye and/or skin and/or respiratory) per the NPG’s suggested preventative measures. The chemicals or substances contained in the NPG include all substances for which NIOSH has recommended exposure limits and those with permissible exposure limits as found in the OSHA General Industry Air Contaminants Standard (29 CFR 1910.1000). However, although a component of a product may not have an REL or PEL, worksite industrial hygienists/safety professionals or product users must evaluate all workplace chemical hazards, including those hazards not presently covered by an established limit.

CONCLUSIONS

Based on the classification system described in this article, the results of the evaluation indicate the PPE requirements specified in SDSs did not substantively differ between polyurethanes and non-isocyanate-containing coating systems.

Only the alkyd products (hand, skin/body protection) and acrylic products (hand protection in half the evaluated SDSs) required more stringent protection compared to the polyurethanes. Protective eyewear was required across all coating groups. Although an SDS may not require PPE, it is recommended practice to wear appropriate PPE until personal-exposure monitoring determines the chemical hazards are below the occupational exposure limits.

Although little variability was found between the six coating groups, variability did exist within the coating systems comprising these six groups. An increase in respiratory protection was required during the spray application of 18% of the products, but overall this variability did not result in a significant difference in PPE requirements during the application of the coatings by spray or brush/roller.

Although not readily apparent in Table 2 and not a specific component of this study, the assessment of the 154 SDSs revealed that the detail and quality of the SDSs varied considerably between manufacturers. Little variability was identified among SDSs supplied by the same manufacturers, i.e., in general, manufacturers did not alter the PPE requirements between products in different coating groups. In addition, many of the SDSs left uncertainty regarding PPE requirements. Except for the eyewear requirements, most glove, clothing and respiratory requirements were recommended as appropriate (i.e., dependent upon the concentration of the hazardous components, the task, site-specific conditions or required a risk assessment). Therefore, the SDS authors avoided definitively specifying PPE. The SDS language was generally crafted in a way to defer the responsibility of determining the appropriate PPE to the workplace industrial hygienist/safety professional or the product end user.

Although not always requiring PPE, many polyurethane SDSs contained special isocyanate warning statements. For example, individuals with lung or breathing problems or prior reaction to isocyanates must not be exposed to vapor or spray mist. Hazardous-component warning statements were not found in the evaluated SDSs for non-isocyanate-containing coating systems.

Conclusions drawn from the assessment of reported PPE requirements for the products evaluated during this study may not be applicable to other products on the market or future products.

Even if not specified in the SDS, good practice dictates that gloves, goggles and a face mask should always be used when applying any coating.

ABOUT THE AUTHOR

Leah Tipton is the EH&S Project Manager at KTA-Tator, Inc. She holds a Doctor of Public Health degree in Environmental and Occupational Health. Tipton has expertise designing and executing air-quality studies including indoor, outdoor and personal-monitoring campaigns.

REFERENCES

- O’Malley, Dan, and Stanford T. Liang, “Worker Health and Environmental Hazards Associated with Coating Application and Removal,” Protective Organic Coatings, edited by Kenneth B. Tator, Vol. 5B, ASM International, 2015, pp. 277–290.

- O’Malley, Dan, “Safety and Regulations,” SSPC Painting Manual, 5th ed., Vol. 1, SSPC: Society for Protective Coatings, 2016, Good Painting Practice, pp. 6–1-6–55.