Primary Contributors to Noise Hazards in the Coatings Industry

Continuous exposure to noise above 85 dBA (adjusted decibels) causes permanent damage to the hair cells in the cochlea resulting in irreversible hearing damage. The National Institute Occupational Safety and Health (NIOSH) recommends 85 dBa as the maximum exposure to noise over an eight hour time period. At 110 dBA, the permissible noise exposure time is one minute 29 seconds. A three-dBA increase doubles the amount of noise, and halves the recommended amount of exposure time. A one-time exposure of 140dBA or greater can cause damage to hearing. In the coatings industry employees are exposed to the numerous noise sources at varying levels. For example: heavy traffic (85 dBA): air compressors (85 dBA to 88 dBA); and abrasive blast cleaning measured at the air discharge (112 dBA to 119 dBA). Employee exposure is not limited to the noise that they are creating, but include the noises generated by adjacent operations.

Continuous exposure to noise above 85 dBA (adjusted decibels) causes permanent damage to the hair cells in the cochlea resulting in irreversible hearing damage. The National Institute Occupational Safety and Health (NIOSH) recommends 85 dBa as the maximum exposure to noise over an eight hour time period. At 110 dBA, the permissible noise exposure time is one minute 29 seconds. A three-dBA increase doubles the amount of noise, and halves the recommended amount of exposure time. A one-time exposure of 140dBA or greater can cause damage to hearing. In the coatings industry employees are exposed to the numerous noise sources at varying levels. For example: heavy traffic (85 dBA): air compressors (85 dBA to 88 dBA); and abrasive blast cleaning measured at the air discharge (112 dBA to 119 dBA). Employee exposure is not limited to the noise that they are creating, but include the noises generated by adjacent operations.

Long-term Effects of Excessive Noise on Hearing

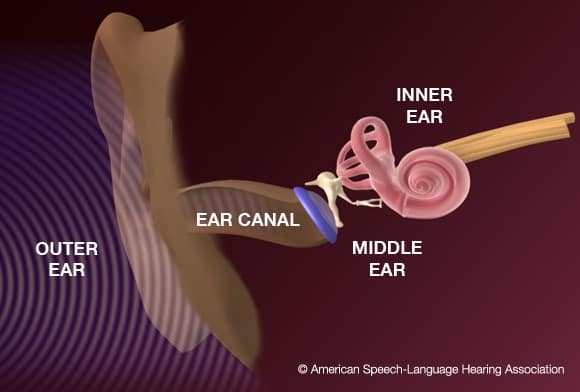

Hearing impairment can be due to a mechanical blockage in the transmission of sound to the inner ear (conductive hearing loss) or damage to the hair cells in the cochlea, part of the inner ear (sensorineural hearing loss). Hazards in the coatings industry lead to Tinnitus, Noise-induced hearing loss, and Ototoxicity.

Hearing impairment can be due to a mechanical blockage in the transmission of sound to the inner ear (conductive hearing loss) or damage to the hair cells in the cochlea, part of the inner ear (sensorineural hearing loss). Hazards in the coatings industry lead to Tinnitus, Noise-induced hearing loss, and Ototoxicity.

Tinnitus is a ringing, hissing or booming sensation in your ears. Tinnitus may last for minutes to hours after the exposure has ended. Tinnitus can be the first sign that your hearing has been or is being damaged by exposure to noise.

Noise-induced hearing loss (NIHL) can be caused by prolonged exposure to high levels of noise. Symptoms include the inability to hear high pitched sounds, progressing to an inability to hear lower pitched sounds. The permanent damage from NIHL can occur from exposure to impulsive noises, such as gunshots. Exposure to impulses may split the eardrum membrane causing painful, but healable damage.

Some organic solvents commonly used in the coatings industry such as toluene are ototoxic substances. Ototoxic substances cause chemical damage to the inner ear that contains both the hearing mechanism and the vestibulocochlear nerve that sends hearing and balance information to the brain. Damage caused by ototoxic substances can range from being small and unnoticeable to high frequency hearing loss, and in extreme cases permanent and complete deafness. Individuals exposed to ototoxic substances along with high noise levels are at a greater risk of hearing damage than those exposed to either noise or substances separately.

Hierarchy of Controls

To prevent employee exposure to noise levels at or above the legal limit, OSHA’s hierarchy of controls are considered, including engineering practices, then administrative controls/work practices, and finally the use of personal protective equipment. Engineering controls may involve making changes at the noise source by way of repairing equipment, replacing equipment with a low noise producing option, positioning noise sources farther away from workers, and installing noise barriers along the transmission path. Administrative controls include, but are not limited to limiting the amount of time the worker is exposed to noise hazard, using the high noise producing equipment at times when fewer workers will be in the area, and by keeping all non-essential personnel away from the noise source. The use of personal protective equipment (PPE) is last in the hierarchy. Hearing protection PPE is available in a variety types, and provide numerous levels of protection, or noise reduction rates (NRR).

The noise reduction rate is the average sound level reduction provided by the hearing protection device in a laboratory test. It does not consider the loss of protection from an improper fit, or if the device is not donned during the entire time of the exposure. OSHA does not require, but recommends that 50% of the NRR be applied rather than 100% of the rate. For example, if a worker is exposed to a noise level of 93 dBA and the hearing protection employed has a NRR of 29 dB, the employee’s exposure is 82dB. How is the exposure level calculated?

Calculation: 8-hr TWA noise exposure on A scale – ((NRR of hearing protector – 7 db) / 2))

- 29 dB – 7 dB = 22dB (subtract 7dB when using the A scale)

- 22dB / 2 = 11 (reduced NRR)

- 93 dBA – 11 = 82 dB (employee exposure level)

There are many varieties of hearing protection devices available; the most common types include ear plugs and ear muffs. Ear plugs may be disposable, or reusable. Disposable earplugs are compressed or rolled down prior to insertion, and then they slowly re-expand to fill the ear canal. They are the most common type of hearing protection and are usually made from PVC or polyurethane foam. Reusable ear plugs are made from materials such a silicone, and are tapered to fit the ear canal. They generally have a lower NRR than disposable ear plugs. Ear muffs are rigid cups with a seal around the ear to block noise. The three common designs of earmuffs are over the head, cap mounted, and behind the ear. Cap-mounted earmuffs are designed to mount directly to most hard hats with side-accessory slots, and behind-the-neck style can also be used while donning a hard hat or face shield. When using both ear muffs and ear plugs, 5dB is added to the NRR of whichever protector (the earplug or the earmuff) has the higher NRR.

There are many varieties of hearing protection devices available; the most common types include ear plugs and ear muffs. Ear plugs may be disposable, or reusable. Disposable earplugs are compressed or rolled down prior to insertion, and then they slowly re-expand to fill the ear canal. They are the most common type of hearing protection and are usually made from PVC or polyurethane foam. Reusable ear plugs are made from materials such a silicone, and are tapered to fit the ear canal. They generally have a lower NRR than disposable ear plugs. Ear muffs are rigid cups with a seal around the ear to block noise. The three common designs of earmuffs are over the head, cap mounted, and behind the ear. Cap-mounted earmuffs are designed to mount directly to most hard hats with side-accessory slots, and behind-the-neck style can also be used while donning a hard hat or face shield. When using both ear muffs and ear plugs, 5dB is added to the NRR of whichever protector (the earplug or the earmuff) has the higher NRR.

OSHA Standards for Hearing Conservation

OSHA addresses Occupational Noise Exposure in the construction industry in 29 CFR 1926.52 (Occupational Noise Exposure), 29 CFR 1926.101 (Hearing Protection), and 29 CFR 1904.10 (Recording Criteria for Cases involving Occupational Hearing Loss). Permissible noise exposure limits are found in 29 CFR 1926.52 Table D-2. A hearing conservation program is required whenever noise exposure to employees equal or exceed an 8-hour TWA of 85 decibels measured on the A scale (slow response) or equivalent. OSHA 29 CFR 1926.52 does not describe the required content of the program, however; the content is described in the General Industry Occupational Noise Standard (29 CFR 1910.95). Per the general industry standard, the hearing conservation program must include:

- Monitoring to evaluate noise exposures

- Employee notification of noise exposures exceeding allowable limits

- Observation of monitoring by employees or their representatives

- Audiometric testing of employees at the start of employment and periodically (e.g. annually) to determine whether occupational noise exposures are contributing to hearing loss

- Training of workers in the hazards of noise, proper use of hearing protection, and the purpose of audiometric testing

- Records of audiometric testing and noise monitoring