KTA Video Learning Series Corrosion Assessment

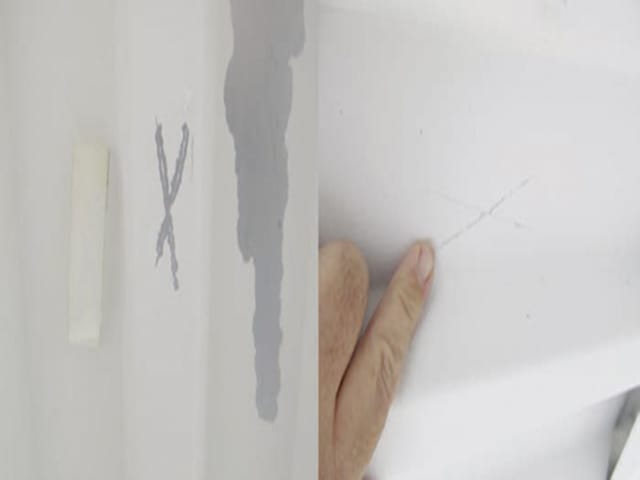

Corrosion Assessment: This video, narrated by KTA’s Vice President Bill Corbett, covers corrosion assessment for the paint and coatings industry. We hope you gain some value from it!

KTA Video Learning Series Corrosion Assessment Read More »