Wet film thickness, or WFT is the measured thickness of any applied wet paint that is liquid-based. A wet film thickness gage should be used by the applicator as the coating is being applied to ensure that the measurement is representative of the calculated wet film before significant solvent evaporation occurs. Even slight delays in taking wet film thickness measurements can result in false low readings, since the solvents may have evaporated from the film before the measurements are acquired, which is why a WFT gage is largely regarded as an applicators tool rather than an inspector gage.

Why is WFT important? Measuring the WFT of a coating enables the applicator to adjust the spray gun speed, number of spray passes and to make spray gun adjustments (when possible) or select other spray tips to apply the correct amount of coating to achieve the specified dry film thickness.

What is the relationship between WFT and production? Time is money. The need to apply a build-up coat or even worse the need to reduce thickness (by sanding) can impede production and reduce profitability. While under-thickness can frequently be corrected by adding more coating, excessive thickness can cause solvent entrapment, runs and sags and, if uncorrected can lead to adhesion problems. Each of these events can negatively impact a project schedule. Perhaps more importantly, the performance properties of most coatings are based on achieving the specified dry coating thickness, and applying the correct wet film thickness can help to meet this requirement. Measuring wet film thickness during application immediately identifies the need for in-process adjustments by the applicator.

How is the WFT calculated? The coating manufacturer may indicate the range of wet film thickness to be applied to achieve the desired dry film on the product data sheet (PDS). However, many manufacturers only list the recommended DFT since the amount of thinner that will be added by the contractor is unknown and that amount effects the target WFT. Specifications typically list the desired end-result (the DFT) and not the means/methods of achieving it (the WFT). The wet film thickness target (or range) can be calculated. The equations for calculating the WFT, both with and without thinner addition, are shown. The dry film thickness range (per coat) is extracted from the specification or the coating manufacturer’s PDS (whichever is the governing document) and the volume solids content is listed on the PDS.

What are volume solids in paint? The volume solids content of a coating is an expression of the film-forming ingredients, or the material left behind after the solvents have evaporated from the applied coating. On a very basic level paint contains solvent, resin, pigments, and additives. The volume solids content is the percentage of the formulation that is non-volatile and will remain on the surface after the coating dries and cures.

Without thinner:

Wet Film Thickness (WFT) = Dry Film Thickness (DFT) ÷ Percent Solids by Volume

Example:

Specified Dry Film Thickness = 3 – 5 mils

Volume Solids Content = 65% (0.65)

WFT = 3 ÷ 0.65 = 4.6 mils; 5 ÷ 0.65 = 7.7 mils

Based on this example, provided the applicator applies between 5 and 8 mils WFT, the specified DFT of 3-5 mils should be achieved.

The equation for calculating the target WFT with thinner added in the shop or field requires that the volume solids content of the coating (as manufactured) be adjusted based on the volume of thinner added, as a percentage of the total volume of coating.

With thinner:

WFT = DFT ÷ (Volume solids content ÷ 100% + % of thinner added)

Example:

Specified Dry Film Thickness = 3 – 5 mils

Volume Solids = 65%

Thinner by Volume = 20% (e.g. added 2 gallons of thinner to 10 gallons of mixed coating)

Step 1: (0.65 ÷ 1.20) = 0.54, or 54% adjusted volume solids based on 20% thinner addition

Step 2: 3 ÷ (0.54) = 5.6 mils 5 ÷ (0.54) = 9.3 mils

Based on this example, provided the applicator applies between 6 and 10 mils WFT, the specified DFT of 3-5 mils should be achieved, even with 20% thinner, which is part of the wet film but not the dry film.

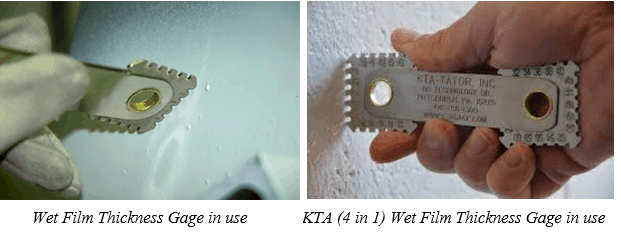

How is WFT measured? Wet film thickness gages are used to monitor the thickness of the applied wet coating to achieve a specified dry film thickness. They measure all types of wet organic coatings, such as paint, varnish, and lacquer on flat or curved, smooth surfaces. The units of measure for these gages is typically micrometers (microns) or mils. Wet film thickness is measured according to ASTM D4414, Standard Practice for Measurement of Wet Film Thickness by Notch Gages. Pictures are gages commonly used to measure WFT.

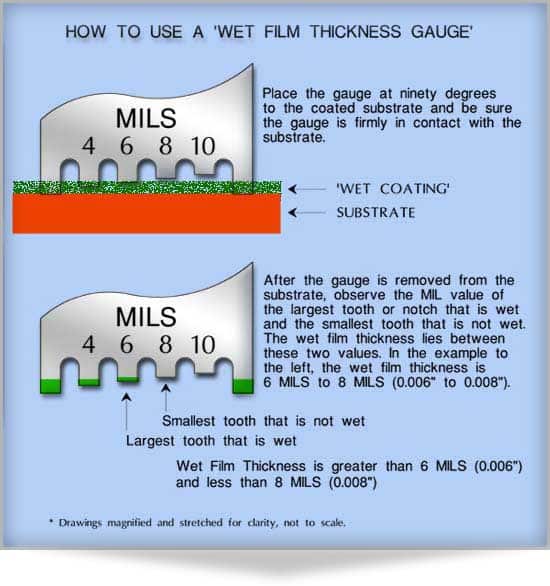

How is a WFT gage used? Using a WFT gage is quite simple. First, verify that the notches (teeth) are clean and free of any dry paint. Immediately insert the end of the gage perpendicularly into the wet coating. The two end teeth will penetrate down to contact the underlying surface and will be wetted with coating. Withdraw the gage and read the highest wetted step. If none of the numbered notches contain wet coating, rotate the head of the gage to a lower WFT range and remeasure. If all of the numbered notches contain wet coating, rotate the head of the gage to a higher WFT range and remeasure. A diagram describing the proper use of a WFT gage is shown. The teeth of the gauge must be wiped off after every individual reading.

What units are used when measuring WFT? Typical units of measure are mils and microns. A mil is a unit of length equal to one thousandth (10−3) of an inch (0.0254 millimeter). A micron is a metric unit of measure for length equal to 0.001 mm, or about 0.000039 inch. Its symbol is µm. 25.4 microns is equal to 1 mil.

Conclusion: Calculating and properly measuring wet film thickness can reduce rework, improve productivity, and help ensure a properly applied coating. The proper use of a WFT gage by the applicator is critical to achieving the desired dry film thickness.

while measuring is there any impression mark spot will apear or not…if its apear again how can we paint..beacause firstly that is wet component the impression make bad design on product..please answer me it is very essential to me….

Mahalingesh, the following comes from the author, Chad Quatman:

Lightly dab the impression with a small paint brush to get the coating to flow back together.