Industrial coatings project specifications invoke many standards and inspection check points that require visual acceptance. Proper illumination of the work area is vital when determining an acceptable product. If there is insufficient light, it is unlikely that a quality inspection of workmanship can be performed. But requiring excessive light and it may not be practical in the field. And use of the wrong kind of light could present a safety concern. Workplace illumination can be difficult to manage as workers must be able to see what they are doing without the light source being obstructive. How can this balance be achieved and what guidance is available?

SSPC-Guide 12 “Guide for Illumination of Industrial Painting Projects” provides specifiers and contractors with information on the quantity and quality of lighting on industrial coating projects that is favorable to achieving safe and productive industrial work places. While there are other lighting standards, Guide 12 is the only guide specific to the coatings industry and contains descriptions of the various types of lighting necessary when specific hazards and operating conditions are present and recommends illumination levels for specific tasks, including: surface preparation, coating application, and inspection.

What is Illumination and Why is it Needed?

Illumination, measured in lux or Foot-Candles (fc), is the measure of the amount of light that falls onto a surface (1fc = 1 lumen/ft2). The level of illumination required depends on the task being performed as well as the location and environment. Adequate illumination improves productivity, while poor illumination increases both the risk of accidents and hinders production. But more light is not always better. Unnecessarily high levels of illumination add to the cost of the work due to installation, power requirements and maintenance, and may negatively impact safety by increasing glare.

Illumination, measured in lux or Foot-Candles (fc), is the measure of the amount of light that falls onto a surface (1fc = 1 lumen/ft2). The level of illumination required depends on the task being performed as well as the location and environment. Adequate illumination improves productivity, while poor illumination increases both the risk of accidents and hinders production. But more light is not always better. Unnecessarily high levels of illumination add to the cost of the work due to installation, power requirements and maintenance, and may negatively impact safety by increasing glare.

The recommended levels of illumination provided in Guide 12 came from objective and subjective examination of a variety of industrial coating workspaces. The recommendations found in Guide 12 are believed to be comfortable for the workers by providing distortion-free work surfaces with adequate levels of illumination to perform their work safely and productively.

How Much lighting is Needed?

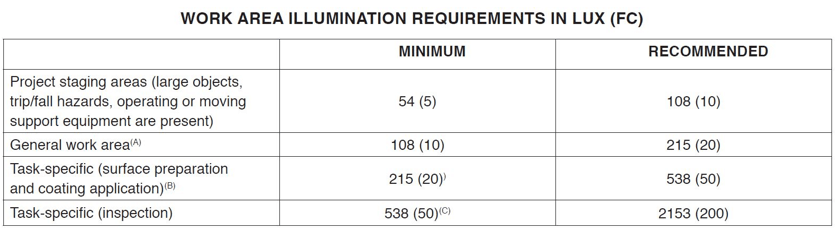

OSHA 1926.56(a) requires a minimum 5 fc for general construction area lighting, and 10 fc for general construction shops. Guide 12 provides similar guidance.

When assessing the illumination of the workplace, one should consider:

- Procedures for measuring illumination levels

- Adequacy of natural and artificial lighting where the work is being performed

- Reduced visibility due to glare/dust

- Color of light

- Safety of lighting equipment

Tips for Achieving Illumination:

Periodically inspect illumination levels to confirm adequate lighting. To measure the light, place or hold a light meter so that the light sensor is perpendicular to the surface that is representative of the work area and is at least six feet away from the nearest light source. Take at least five readings in this area and record the average of the measurements. Do this for each task in their respective locations.

Some natural light will be present in most work areas during the day but is not consistent and must be assessed prior to work and monitored as weather conditions and time of year change. Artificial lighting will need to be maintained and adjusted as the work progresses. It is recommended that the lighting systems be protected from the direct spray of coatings and abrasives. Lighting fixtures may not properly disperse heat if overspray or abrasive accumulates, leading to overheating. Due to the harsh environments, the lights will need to be cleaned regularly and possibly replaced.

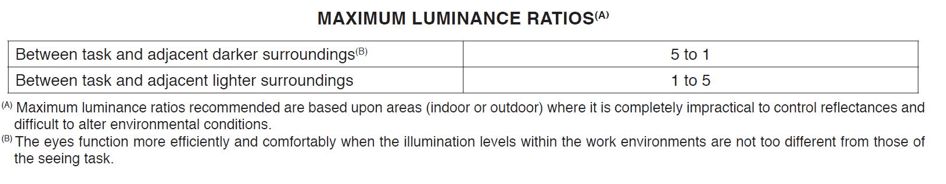

Glare is the effect of light that causes discomfort and impaired vision. It is typically experienced when an area is excessively brighter than the general surroundings. The table below provides MAXIMUM LUMINANCE RATIOS.

The effects of airborne dust will also reduce visibility and limit the amount of illumination of the work place. This will need to be taken into consideration during abrasive blast cleaning operations.

The color of light should be as close to natural daylight. White light is recommended as it does not visually distort the surface.

Before beginning work, the location must first be evaluated to determine if a hazardous atmosphere exists. The condition of the atmosphere during work must also be considered. All lighting equipment needs to be designed for the intended work environment. Because of the environment created with industrial coatings, it is preferred that the light fixtures be encased in a nonconductive, shatterproof casing to prevent electrical shock and be protected from abrasion and corrosion.

Proper illumination can increase productivity and provide a safe work environment. When workers can see what they are doing, the amount of rework required can be reduced. Further, the quality of the work can be better evaluated under proper illumination. You can’t inspect what you can’t see… so if you can’t see, you can’t inspect!