KTA’s Certified Coating Inspector Forum Volume 2, Issue No. 4 – April 2023

William Corbett, COO

AMPP Senior Certified Coating Inspector & Certified Protective Coating Specialist

KTA’s Certified Coating Inspector Forum is designed to provide professional development/continuing education on standards, inspection practices, new instruments, and other topics to help keep certified AMPP and FROSIO coating inspectors current. It represents the views of the author and KTA-Tator, Inc. It may or may not represent the views of AMPP: The Association for Materials Protection & Performance, even though SSPC, NACE, and AMPP standards are frequently referenced in the content.

Introduction

A December 2017 posting to KTA University [1] introduced the concept of using a special scanning probe connected to a continuous read device to collect a larger population of dry film thickness (DFT) datapoints across a structure or element. In 2019, a follow-up column was posted to KTA University [2], announcing that an appendix (Appendix 10) was added to SSPC-PA 2 (published November 2018) titled, Procedure for Obtaining a Greater Population of Thickness Measurements Using Type 2 Gage Continuous Read/ Scanning Probe Technology.

The basis for the new Appendix 10 was research conducted in 2016 by Vision Point Systems, Inc. in conjunction with the US Naval Research Laboratory [3], which demonstrated that greater precision of DFT measurements can be attained using a scanning probe method over the traditional “place and remove” probe method. The research indicated that the increase in precision of rapid scanning DFT measurements over the traditional measurement frequencies described in SSPC-PA 2 can be substantial, and that rapid DFT scanning technology enables an operator to collect a larger number of measurements in a shorter time frame than the traditional method. As a result of the increased number of measurements collected, better estimates of the DFT mean can be obtained through increased precision.

Appendices to SSPC standards are frequently nonmandatory unless they are invoked by the contract documents, so while there was perceived value to invoking Appendix 10 on projects where the consistency of dry film thickness is more critical (e.g., ballast tanks in ships), it was rare to see scanning probe/continuous read technology specified. The reasons for this are unknown; however, it is likely that the industry either didn’t know the technology was available, was satisfied with the status quo, or was reluctant to invoke a new inspection procedure for fear of driving up project costs. But as trained/certified coating inspectors we need to be prepared to perform all methods of dry film thickness measurement, as specifications could begin to adopt the scanning/continuous read methodology in the future.

Why Consider Scanning/Continuous Read Versus Place and Remove Probes?

Let’s assume that SSPC-PA 2, but none of the appendices, has been specified. Let’s also assume that the total coated area to be measured is approximately 10,000 square feet. Based on the frequency of measurement described in the body of SSPC-PA 2, 12 areas (each approximately 100 square feet), 60 spot measurements (5/area), and a minimum of 180 gage readings (minimum 3 per spot) would be required. While that sounds like a lot of gage readings, it represents only a fraction of the total coated area. Using this example and the 1.5-inch spot measurement area, 90 square inches (60 spots x 1.5-inch) of the 1,440,000 square inches of coated steel (10,000 square feet x 144 square inches/square foot) would be measured, which is 0.000063-sq. in. So it should be obvious that the frequency of measurement invoked in the body of SSPC-PA 2 addresses only a fraction of the coated surface, but represents a reasonable balance between quality (DFT measurements) and productivity (application of the coating system) based on using magnetic pull-off (Type 1) or electronic (Type 2) DFT gages that use the “place and remove probe” technology to obtain coating thickness measurements.

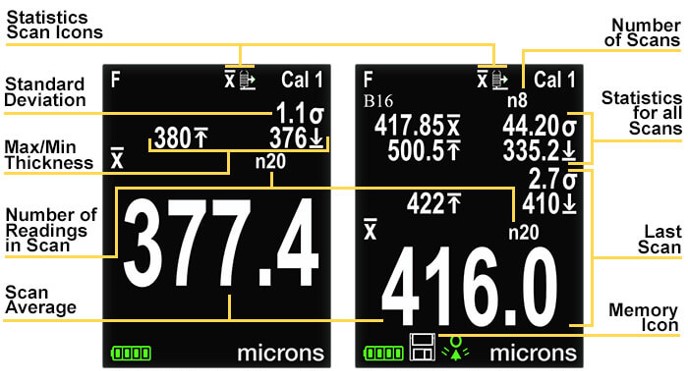

The advent of scanning probes connected to continuous read devices enables a QC or QA inspector to sample a much greater percentage of the coated surface area without extending inspection time. These gages, available from at least three manufacturers, gather readings at a rate of one/second, and will continue to read and store data as long as the probe maintains contact with the coated metal surface. By batching and even sub-batching the data, thousands of readings can be taken using a variety of probe-traversing patterns, depending on the configuration of the item being inspected (e.g., plate steel, pipe spools, I-beams, etc.). But based on the research conducted in 20163, a scanning batch measurement of 12-24 readings is sufficient; in fact, obtaining greater than 24 readings in a scan does little to improve the quality of the data. The 12-24 gage readings can be obtained using an infinity-shape, S-shape, or straight-line pattern in say, a 1 square foot area. Depending on the shape of the item being inspected, multiple areas can be scanned to assess the thickness across a greater percentage of the coated area.

Using Scanning/Continuous Read Technology During a Traditional “SSPC-PA 2 Frequency” Inspection

During a traditional dry film thickness inspection using the frequency prescribed in Section 8[4] of SSPC-PA 2, a minimum of three gage readings are acquired in a 4-cm (1.5-in.) diameter circle defining the spot. Unusually high or low readings are discarded and measurements continue until three readings are obtained in the spot. For each gage reading, the gage probe is repositioned within the spot and another reading is taken. So, the gage operator picks up and sets down the probe a minimum of three times, averages those readings to obtain a spot measurement, then repeats this process in four more locations within a 100 sq. ft. area. This process can be performed much more efficiently by using scanning/continuous read technology. The operator simply moves the probe in a circular motion (1.5-inch circle), without lifting the gage probe from the surface until the motion is complete (effectively “tracing” a circle on the coated surface with the probe). In the process, the minimum three gage readings are collected and averaged before moving to the next spot. Five spot measurements can be obtained more quickly using this process, while still conforming to the requirements of Section 8 in SSPC-PA 2.

An Avenue to Help Encourage Adoption of Continuous Read/Scanning Technology

AMPP Guide 21614, Guide for Improving the Statistical Quality of Dry Coating Thickness Data on Ferrous and Non-ferrous Metal Substrates Using Continuous Read/Scanning Technology was published in April 2023. This guide is intended to inform specifiers about the use of continuous-read or scanning technologies for quickly obtaining large numbers of coating thickness readings.

The guide discusses the rationale and method for improving the statistical quality of DFT data by collecting a larger, more representative data set compared to the frequency of measurements described in Section 8 of SSPC-PA 2. The Guide provides supplementary information on the procedure for obtaining measurements contained in Appendix 10 of SSPC-PA 2.

The guide also presents a summary of past research that provides evidence of improved statistical quality of coating thickness data, reviews existing standards referencing continuous read/scanning technology, describes instrumentation requirements, explores various probe traversing patterns based on the geometry of the structure/item being inspected, presents the advantages and limitations of employing continuous read/scanning methodology, proposes best practices for data management, and provides suggested language to assist the specifier in invoking scanning DFT requirements.

SSPC-PA 2 (April 2022 version) and AMPP Guide 21614 (April 2023) are both available from the Association for Materials Protection and Performance (www.AMPP.org).

Summary

Measurement of dry film thickness is arguably the most common inspection hold point invoked by specifications governing the application of coatings in industrial and marine environments. Continuous read/scanning technology is readily available and can be specified when a project would benefit from a greater population of thickness measurements to help ensure consistency of the applied coating across large surfaces. This same technology can also help speed-up the data collection process on a standard “SSPC-PA 2 DFT inspection.” As trained and certified inspectors we have an obligation to remain current with new and better inspection technologies, independent of whether they become mainstream in the future.

[1] Using Scanning Probe Technology to Measure Coating Thickness, www.ktauniversity.com, December 2017

[2] Addition of Appendix 10 to SSPC-PA 2, Procedure for Determining Conformance to Dry Coating Thickness Requirements, www.ktauniversity.com,April 2019

[3] Paper No. 334110 – 2017 Department of Defense – Allied Nations Technical Corrosion Conference – Statistical and Technical Evaluation of Rapid Dry Film Thickness (DFT) Measurement Technologies; Jeff O’Dell, Wayne McGaulley, and Evan Parson: Vision Point Systems, Inc.; John Wegand, Paul Slebodnick, and Jimmy Tagert: U.S. Naval Research Laboratory

[4] Section 8: Required Number of Measurements for Conformance to a Thickness Specification

Dear Sir

Great article

I follow your advice and information since 2008 – Using Coating Inspection Instruments – William D. Corbett, KTA-Tator.

When in the contract is PA2 , I survey with your instructions that should be fully understood before start

• gage calibration

• Verification of Gage Accuracy on Certified Coated Standards or Certified Shims

• Base Metal Reading Acquisition or Gage Adjustment (using certified or measured shims)

• Measurement of Coating Thickness

• Correction for Base Metal Reading (if acquired).

The research on Continuous Read/ Scanning Probe Technology indicates that the increase in precision of rapid scanning DFT measurements over the traditional measurement frequencies described in SSPC-PA 2 is substantial

Since the advent of scanning probes connected to continuous read devices enables a much greater percentage of the coated surface area without extending inspection time,

Defelsko Scanning Probe is a powerful inspection tool

Thank you for the feedback, we’re glad you find our articles useful.