A 1930s-era riveted steel tank with a capacity of 1.5 million gallons was one of the largest water tanks in the world at the time of its construction. A radial cone-design tank with a 6-foot-diameter riser and 20 legs, it is approximately 175 feet in height and 80 feet in diameter. The available painting history indicated the tank was fully painted in 1986 and touched up in 1996. The tank exterior was abrasive blast-cleaned and painted in 2009.

As seen in JPCL February 2017

The controlling specification, “Cleaning, Painting, and Miscellaneous Repairs of 1.5 Million Gallon Steel Elevated Water Storage Tank,” required that all exterior surfaces be blast-cleaned to a commercial grade in accordance with SSPC-SP 6, “Commercial Blast Cleaning,” but it provided a description of commercial blast-cleaning from an outdated version of SSPC-SP 6 (September 15, 1994). The specification went on to state that, “where questions arise regarding the degree of cleaning performed, pictorial standards of the Steel Structures Painting Council, Guide to Visual Standard No. 1 shall be used”. It should be noted that the reference pictures in the visual guide did not change between the time the outdated version of SSPC-SP 6 was in effect and the time the current version of SSPC-SP 6 was issued, which, incidentally, preceded the date the contract became effective.

The specification called for a three-coat epoxy-epoxy-polyurethane system to be applied to the tank exterior. The painting operations commenced in 2009 and finished in the winter of 2010. The contract work was given final acceptance in May of 2011 after an independent third-party inspection firm inspected the painting work.

Within the warranty period of the completed project — about mid-year of 2012 — some coating failure was visible on the tank roof overhang. The original inspection firm conducted an inspection of the tank roof overhang, along with other areas where peeling or cracking paint were found on the tank shell and rooftop. The inspection report noted peeling coating in 10 locations and some cracking. No corrosion was noted to be present on the surface of the exposed primer in areas of delamination. Based on the inspection firm report, the owner concluded that the paint failure under the roof overhang appeared to be localized and not spreading over the entire surface. The owner accepted a recommendation that the localized areas of delamination be repaired by removing loose paint using power tools until paint with good adhesion was found, then followed by re-application of the coating system. It was also recommended that the areas of cracked coating be sanded down to remove the surface cracking and topcoated with polyurethane.

In the spring of 2013, the painting contractor asked to correct coating defects that arose during the warranty period but was not permitted to do the touch-up work at that time.

- The owner engaged a consultant who examined the tank in early 2014. The consultant’s observations included the following.There was extensive delamination of the intermediate and topcoat from the primer.

- There were numerous runs and sags in the coating film and some had cracked and peeled.

- Metallic abrasive (as required) was not used, as indicated by inspection reports.

- Coating adhesion tests were performed in the general vicinity of the delamination. The adhesion of the primer was reported to be good (4A when tested in accordance with ASTM D3359). The adhesion of the general system was measured at three locations and reported to be variable.

- The dry film thickness (DFT) of the coating system was general higher than the specification requirement.

- In areas of delamination, some corrosion could be found on the surface of the primer.

- Pits were not filled.

- Pictures of the original, unidentified abrasive blasted-cleaned surfaces indicated that areas of the blasted substrate were in non-compliance with the specification.

- The consultant recommended spot repairs to remedy areas of coating delamination and spot abrasive blast-cleaning to correct excessive coating thickness, whether the coating was failing or not. Later that same year, the consultant revisited the tank and made additional observations, which are paraphrased as follows.

- Each of the legs had numerous pits that had not been filled and numerous runs and sags in the coating. No coating delamination was found on any of the legs. There was abrasive embedded in the coating to some unidentified extent on each leg. Some of the legs had pinpoint rusting.

- Coating adhesion was measured in 87 locations; 86 were found to be good to excellent (3A to 5A) and one result marginal (2A).

- The coating thickness was generally greater than required by the specification.

- Rust was visible on the bottom of the bowl.

- Excessive coating thickness was found on some of the rivets and in some cases the coating was cracked.

The consultant’s report did not quantify the amount of coating failure (corrosion, paint delamination, cracking) present on the tank. The consultant’s additional visit confirmed that the coating adhesion was satisfactory on 98.9 percent of the surfaces tested. His repair recommendation was changed from conducting spot repairs to complete removal and replacement of all tank exterior coatings.

The consultant prepared an additional letter in mid-2016, which commented on photographs that were taken during a second consultant’s site visit on behalf of the owner. It stated that the photographs “are graphic evidence of the progression of the premature failure of the coatings that were applied to this tank the last time it was painted.” The consultant also stated that it is common practice in the coatings industry to remove all existing coatings if 25 percent or more have failed, noting that, “this is not a published standard, but is recommended by most experts in the coating industry.” The rationale used is that if 25 percent or more has failed, it is highly likely that the remaining 75 percent will also fail in a short time, and argues that the progression of the failure from late 2014 to the present time is evidence of the accuracy of the premise.

The owner asked the second consultant to examine the coatings on the tank exterior in order to reconcile the first consultant’s change in recommendations.

FIELD INVESTIGATION

The second consultant examined the elevated water tank coatings in early 2016 and again in mid-2016 to determine the degree of rusting and to perform coating thickness measurements and adhesion testing.

The percentage of rusting and coating breakdown on the tank was assessed using SSPC-VIS 2, “Standard Method for Evaluating Degree of Rusting Painted Steel Surfaces.” The distribution of rust is classified as spot rust, general rust or pinpoint rust. Spot rusting occurs when the bulk of the rusting is concentrated in a few localized areas of the painted surface. General rusting describes rust spots of various sizes randomly distributed across the surface. Pinpoint rust is distributed across the surface as very small individual specks of rust. In some instances, the rust present is a hybrid of these three patterns and may be described using combinations of the rust grades.

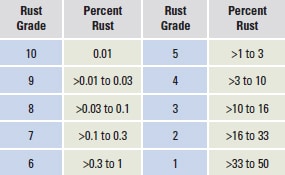

The extent of rust is evaluated as a percentage of the total surface area examined. The percentages follow a logarithmic scale and are ranked as Rust Grades (Grade 10 to Grade 1) representing by the percentages of rust in Table 1.

TABLE 1: RUST GRADES

Coating adhesion was assessed in accordance with ASTM D3359, Method A, “Standard Test Methods for Measuring Adhesion by Tape Test.” This method involves making two intersecting cuts through the coating to the substrate with a sharp blade. A special pressure-sensitive tape is applied to the X-cut area and rapidly removed. The adhesion of the coating is rated based on the amount of coating removed by the tape using the following ASTM scale.

5A – No peeling or removal.

4A – Trace peeling or removal along incisions.

3A – Jagged removal along incisions up to 1/6-inch on either side.

2A – Jagged removal along most of incisions up to 1/8-inch on either side.

1A – Removal from most of the area of the X under the tape.

0A – Removal beyond the area of the X.

Coating thickness measurements were in general accordance with ASTM D7091, “Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metal.”

The results of the field investigation are summarized as follows.

- The coating on the support structure (tank legs and associated steel below the balcony level) was in excellent condition (Fig. 1). Corrosion on the support structure was minimal (>0.3 to 1.0 percent) and generally localized at rivets or between back-to-back steel members. There were random runs and sags in the coating (Fig. 2).

- There was some cracking of the coating, but the cracking was limited to the anchor plate areas that were readily accessible from the ground. There was no evidence of cracking, delamination or other coating defects on the remainder of the support structure that would compromise the integrity of the coating system.

- The shell of the tank was in fair condition. There was random peeling of the topcoat and intermediate coat on the tank shell and under the roof overhang (Fig. 3). The total area of peeling relative to the tank shell and overhang area was approximately 1 percent. Corrosion on the shell was less than 0.1 percent.

- The leg extensions (leg beams above the balcony level) were in poor condition with extensive cracked coating and but only some corrosion. The coating in these areas was excessively thick, possibly to completely cover the rivets. The paint was also excessively thick and cracked on the bottom angle of the balcony. The cracking contributed to rust staining, but rust was limited to 16 percent of the angle surface (Fig. 4).

- There was some rusting on the bottom plate of the balcony, limited to less than 3 percent of the surface area.

- The reservoir bowl (from the balcony down) had rusting on approximately 5 percent of the surface area. The rusting had the characteristic appearance of pinpoint rust, which is typically associated with coating applied at insufficient thickness. However, the rusted areas were not accessible to measure the coating thickness.

- The roof was in relatively good condition with rust limited to less than 0.1 percent of the surface. The coating had cracked on about 15 percent of the weld seam surfaces.

- The adhesion of the coating was measured in 11 locations on the tank shell, roof and balcony and was satisfactory (3A or better) in 9 of the 11 locations (Fig. 5). The adhesion was also measured at ground level on the legs and the riser and found to be good (4A or better).

- The thickness of the coating was measured in numerous, random locations on the balcony, sidewall, leg extensions, handrails and the roof. The overall thickness of the coating was found to range from 3 mils (on a handrail) to 45 mils (on the balcony bottom angle), with an average of 18.9 mils. Cracking was evident in areas of higher coating thickness readings.

- The condition of the coatings on the tank was documented photographically from the ground using a high-definition digital camera. Additionally, examples of typical coating defects were photographed from the balcony.

DISCUSSION

The results from the second consultant’s field investigation indicate that the tank’s coating is in satisfactory condition and only needs touch-up painting to return to a condition that will meet or exceed the expected service life for the epoxy-epoxy-urethane system applied.

The support structure is in excellent condition considering that the coating has already been in service for nearly six years. There is minimal corrosion on the support structure, which is somewhat unusual for a tank of riveted design. Even with careful painting on this type of structure, the numerous gaps and crevices created by the rivets and back-to-back pieces of steel create areas where slight expansion or contraction of steel elements can cause the coating to crack and rust to form. In this case, the corrosion was limited to less than 0.1 percent of the surface of the support structure, which is excellent. There is some coating cracking at the anchor plates, but the minimal corrosion on the legs and the cracking of anchor plates can be effectively repaired on a spot-repair basis.

The tank reservoir contains a few coating problems, which cover a small percentage of the surface. There is visible delamination of the topcoat and sometimes the topcoat and intermediate coat. The coating delamination is limited to approximately 1 percent of the tank reservoir sidewalls and beneath the roof overhang. This low percentage of coating delamination can certainly be repaired on a spot basis and does not require removal of the coating system or even removal of all of the topcoat. There are several methods that can be employed to prepared spot-repair areas of delamination, such as brush-off blast-cleaning and high-pressure waterjetting.

There are some areas that require more extensive repair, including the leg extensions (the tops of the leg columns above the balcony) and the lower angle of the balcony. These structural pieces have relatively thick paint that has cracked and rusted in some spots. Power tool cleaning to bare metal or spot abrasive blast-cleaning and re-application of the coating system on the cleaned surfaces is recommended. Overall, less than 1 percent of the surface of the reservoir is affected.

The coating on the roof requires minimal attention. Cracking along weld seams is limited to about 15 percent of the total lineal feet of welds. There is very little corrosion on the roof and spot touch-up after power tool cleaning can be performed to repair cracking and rust spots.

Approximately 5 percent of the bottom of the bowl is experiencing surface rusting, which forms when the coating is applied at an insufficient thickness. At this point, it may be necessary to remove the coating by spot abrasive blast-cleaning and re-apply the coating system.

Although the corrosion on the tank was minimal after six years in service, it is undoubtedly greater than it was one or two years after the tank was put into service. Corrosion at the areas of delamination on the sidewalls was not noted in the 2012 tank examination report from the inspection firm. Had the painting contractor been permitted to perform the warranty touch-up work in early 2013, it is likely that very little rust would have formed — if any at all. A typical tank-painting program includes warranty repair of visual defects that arise during the first year of service. Typically, missed areas and areas of poor adhesion will reveal themselves after the coating system goes through a full year-long weather cycle. When coating failures are not repaired within the first year or two, the defects that could have been eliminated during (or shortly after) the warranty period will expand as small unrepaired spots of rust and then grow larger because corrosion undercuts the adjacent coating layers. Areas of slight surface rusting that could be easily repaired by simply power-washing and overcoating become more severe, reaching a point where spot removal or increasingly rigorous and expensive repair procedures are necessary.

The specification required that the contractor repair defects that arose at the one-year anniversary (warranty) inspection, which is normally performed twelve months following final acceptance of the coating work. However, in this case, the extent of warranty repairs present at the anniversary inspection was not properly documented. The coating was examined by a consultant in 2014, almost four years after completion of the coating application and more than three years after the anniversary inspection. The 2016 examinations of the tank occurred five-to-six years after completion of the painting and the results were significantly worse than would have been the case if the warranty repairs were completed immediately following the warranty period. Even though the coating system aged for several more years, as of 2016 it did not require removal and replacement.

The original consultant’s report in 2014 opined that spot-repairing the tank would be adequate and reasonable. It was also stated that the runs and sags should be repaired because they will fail in the future, which has no technical basis. Runs and sags in the coating were at least five years old at the time of the original consultant’s report and fully cured. Runs and sags may develop cracks when the coating shrinks during drying and curing as the solvent from the coating evaporates and the coating films crosslink. There is no basis to argue that the runs and sags in a coating that is five years old will suddenly develop curing stress-cracking. The presence of runs and sags without cracking is not a warranty issue. Runs and sags in the coating are clearly visible upon inspection. However, the coating was accepted by the owner and runs and cracks did not develop during the warranty period.

Similarly, areas of excessive or insufficient coating thickness that did not contribute to coating failures during the warranty period and were not corrected as a deficiency during project execution are not defects to be corrected.

The consultant’s recommendation from the first report in 2014 (spot repairs) was subsequently changed to total removal and replacement of the coating system following a second examination in 2016. This recommendation change is not justified since the second investigation did not document additional quantified defects. In fact, additional adhesion testing determined the adhesion on the tank was good.

The consultant opined that if 25 percent or more of the coating is failing, then all the coating should be removed and replaced. However, the actual amount of coating failure was never quantified in either report.

Runs, sags and insufficient or excessive thickness are not coating failures. A clear majority of the coating on the areas of the tank that had runs and sags and/or coating thicknesses outside of the specified range are experiencing no coating failure at all. Corrosion, coating delamination and cracking are coating failures, but the total affected surface area of these defects is under 2 percent and nowhere near the 25 percent that was cited as the threshold.

CONCLUSIONS

The elevated water tank coating only needs touch-up painting to return to the condition that will meet or exceed the expected service life for an epoxy-epoxy-urethane system.

The combined coating delamination, corrosion and other coating failures affect less than 2 percent of the total surface area of the tank.

Based on the contemporaneous documentation, it appears that if the coating contractor been permitted to perform the touch-up painting necessary to correct coating failures found during the anniversary inspection, minimal — if any — touch-up coating would have been necessary in 2016.

The opinion that the coatings on the tank need to be totally removed and replaced is not supported by the facts. Complete removal and replacement of the coating is unnecessary at this time.

ABOUT THE AUTHOR

Cynthia O’Malley is the vice president and group manager of the professional services business unit at KTA-Tator, Inc., and co-chair of SSPC’s Women in Coatings Program. During her more than 20 years with KTA, she has been active in several industry organizations. O’Malley is an SSPC-certified Protective Coatings Specialist, a member of ASTM International and past-president of the Pittsburgh Society for Coatings Technology (PSCT). Her industry honors include SSPC’s 2013 Presidents’ Lecture Series Award and 2015 Women in Coatings Impact Award.

Cynthia O’Malley is the vice president and group manager of the professional services business unit at KTA-Tator, Inc., and co-chair of SSPC’s Women in Coatings Program. During her more than 20 years with KTA, she has been active in several industry organizations. O’Malley is an SSPC-certified Protective Coatings Specialist, a member of ASTM International and past-president of the Pittsburgh Society for Coatings Technology (PSCT). Her industry honors include SSPC’s 2013 Presidents’ Lecture Series Award and 2015 Women in Coatings Impact Award.