Introduction – Cast iron and ductile iron can be coated with a variety of coating systems for both beautification and protection. The selection of specific coatings depends on the service environment and the requirements for aesthetics.

Coatings for cast iron are discussed below for general atmospheric exposure of cast iron surfaces and for underground exposure for buried cast iron pipe, including exterior coatings and interior linings.

Coatings for Cast Iron/Ductile Iron in Atmospheric Exposure

A variety of coatings are suitable for general atmospheric exposure of cast iron. The selection of coatings or a coating system depends primarily on the type of structure, exposure environment, and requirements for corrosion protection. Coatings and coatings systems that are typically used, in general order of increasing performance characteristics, are alkyds, acrylics, zinc-rich primers*, epoxies, and polyurethanes. Some other high-performance coatings are polyaspartics, polysiloxanes, and fluoropolymers. *(Zinc-rich primers are typically used as part of a system with epoxy and/or polyurethane coatings)

Alkyds

As a class, alkyd coating systems have been widely used in the past for corrosion protection. While they are characterized by limited chemical and moisture resistance and relatively poor alkaline resistance, their low cost, ease of mixing and application, and excellent penetration and adhesion to relatively poorly prepared surfaces make alkyds a viable option for application to iron exposed to a non-chemical atmospheric service. Alkyd coating systems typically include a primer and one or two alkyd finish coats, and require less surface preparation (e.g., hand- or power-tool cleaning), compared to high-performance systems. A variety of formulation modifications are also possible with alkyd coatings to improve specific characteristics. A common modification is the incorporation of silicone to produce a “silicone-alkyd” coating, which is used as a finish coat. These coatings have improved durability, gloss retention, and heat and moisture resistance. While alkyd coatings have a successful history of use in atmospheric exposures, current restrictions on volatile organic compounds (VOC) are limiting their use today.

Acrylics

Acrylic coatings constitute a versatile category of products with a wide range of properties and are generally used in mild to moderate environments. These coating are typically waterborne, although solvent-borne formulations are possible (but may require baking to achieve cure which limits field use). Waterborne acrylics cure by water evaporation and coalescence of the coating particles into a solid film. The water content of the coating limits curing capabilities at lower temperatures – acrylics generally will not cure properly below 50 F. Acrylic systems generally include an acrylic primer and one or two finish coats. Acrylics may also be used as a finish coat over other coating types in higher-performance systems (e.g., over an epoxy intermediate coat).

Zinc-rich primers

High-performance anticorrosive coating systems for steel typically include the use of a zinc-rich primer – the same can be true for cast iron substrates. Zinc-containing coatings offer the added benefit of providing sacrificial protection to prevent the iron from corroding. This helps to eliminate the occurrence of pitting corrosion at voids, pinholes, scratches, and abrasions in the coating system.

Zinc-rich coatings fall into two broad categories: coatings based on inorganic or organic binders. Inorganic zinc-rich coatings are based on a silicate-type binder and are further classified by their curing mechanism. Commonly used inorganic zinc-rich primers are based on ethyl silicate, and cure by reaction with atmospheric moisture. Inorganic zinc-rich coatings generally provide better sacrificial protection than organic zincs, but are less tolerant of deficient surface preparation, are somewhat harder to mix and apply, exhibit a greater tendency to mudcrack at excessive thickness, and are more difficult to topcoat. While inorganic zinc-rich coatings are normally used as a primer in multicoat systems, they can serve as a single-coat, stand-alone system in many environments. The primary drawback of not topcoating, however, is aesthetics.

Organic zinc-rich coatings are most commonly formulated with epoxy, urethane, and moisture-cure urethane binders. The drying, hardening, and curing characteristics of organic zinc-rich coatings reflect the properties of the type of binder used. The organic nature of these zinc-rich primers makes them slightly more tolerant of deficient surface preparation, as they more readily “wet” and seal poorly prepared surfaces, where residues of rust or old paint may remain. Similarly, topcoating with the same generic type of topcoat (an epoxy zinc-rich primer top-coated with an epoxy intermediate or finish coat) is more successfully accomplished, because organic zinc-rich primers generally are characterized by a less porous surface than inorganic zinc-rich coatings.

Both inorganic and organic zinc-rich coatings require blast cleaning to a bare metal surface and sufficient surface profile for the zinc coating to adhere.

Epoxies

Epoxies are two-component coatings known for their tough cured film and superior corrosion and chemical resistance properties. Many types of epoxy formulations are available, and they can be tailored to meet specific requirements. Epoxies cure by chemical reaction of two components—the resin part and the curing agent part—resulting in a dense coating film that provides excellent chemical resistance, and water resistance that is capable of immersion service.

The curing agent is generally a polyamide- or polyamine-based material. Polyamide epoxies are known for their corrosion resistance, while amine-cured epoxies typically provide better chemical resistance. The only significant disadvantages with epoxies are their weathering characteristics—epoxies inherently “chalk” with exposure to sunlight (ultraviolet radiation)—and their relative inflexibility when cured, which may cause problems if substrate movement is an issue. For exterior exposure, an epoxy primer or intermediate coat is typically topcoated with a polyurethane or acrylic finish.

Polyurethanes

Polyurethane coatings cure by chemical reaction and are typically two-component products. The cured film is hard and dense, similar to epoxy, but generally of a lesser thickness and with greater flexibility. Polyurethane coatings possess excellent chemical resistance, and aliphatic formulations provide good resistance to weathering. They are typically used as a finish coat over epoxies and some formulations can be used in immersion service. The curing agent for polyurethanes is an isocyanate material, and safety precautions must therefore be followed during application.

Polyurethanes are also available as single-component materials that cure by reaction with moisture in the surrounding atmosphere. These “moisture-cure urethanes” offer many of the same high-performance characteristics of two-component urethanes in a single-pack product. Moisture-cure polyurethane coatings are generally more user-friendly than two-part coatings, can be more surface tolerant, and can be applied in a wider range of temperatures; significantly, much cooler application temperatures can be tolerated. When a moisture-cure urethane finish is used, a moisture-cure urethane zinc-rich primer and a moisture-cure urethane intermediate coat are typically selected for the system.

(ref: Photo from the Architect of the Capital https://www.aoc.gov/capitol-hill/architecture/cast-iron)

Polyaspartics

Polyaspartic coatings are modified polyureas with application and performance properties similar to polyurethanes. One difference from polyurethanes is an increased application thickness, typically 6 to 9 mils DFT compared with 2 to 4 mils for polyurethane. This increased thickness may allow for the elimination of an intermediate coat when applied to blast-cleaned steel; in this case the system would include a zinc-rich primer and the polyaspartic finish. As is always the case, surface-preparation methods and primers as recommended by the coating manufacturer should be employed.

Polysiloxanes

Polysiloxanes are silicon-based coatings that offer a high degree of thermal stability and heat resistance as compared to coatings based on typical organic compounds. These properties give polysiloxanes excellent weathering characteristics. Polysiloxanes are applied to a relatively higher application thickness than the other coatings reviewed here except for polyaspartics—generally in the 3 to 7 mils DFT range. As with polyaspartics, the increased film thickness may allow for use of a two-coat system (zinc primer and finish coat) on blast-cleaned steel rather than a three-coat system.

Fluoropolymers

Fluoropolymer coatings are generally regarded as being unmatched in terms of weathering resistance. These coatings, however, carry a higher cost and exhibit less tolerance for application error than the other types of coatings. Field applied fluoropolymer coatings generally are fluro-urethanes – i.e. fluorine modified urethanes – or fluorinated ethylene vinyl ether (FEVE). These coatings provide a high degree of mechanical hardness, abrasion resistance, chemical resistance, thermal stability, and resistance to weathering.

Coatings for Cast Iron/Ductile Iron for Underground Service Conditions

The coating options for underground service conditions, i.e. buried iron pipe, differ due to the unique conditions that may be encountered. The first step in determining coating requirements for the exterior of buried iron pipe is to determine what level of corrosion protection is needed based on the soil conditions. A common evaluation procedure was established by the Cast Iron Pipe Research Association (predecessor to the Ductile Iron Pipe Research Association [DIPRA]) in the 1950’s. The procedure consists of evaluating soil in five categories: resistivity, pH, redox potential, sulfides and moisture. The evaluation system assigns points for each category and a cumulative score of 10 or higher indicates corrosive conditions. The system is included in the Appendix to ANSI/AWWA C105, “Polyethylene Encasement for Ductile-Iron Pipe Systems,” which is referenced in the following discussion for polyethylene encasement. (Ref: Polyethylene Encasement, Revised 2-12, Ductile Iron Pipe Research Association)

Exterior Coatings for Underground Service

Exterior coating options for underground service include polyethylene encasement, asphaltic coating, epoxy, fusion bonded epoxy, polyurethane, polyurea and thermal spray metallic coatings. Tape wrap coatings are also discussed as they apply to pipe joints and fittings. It should be noted that asphaltic, epoxy, fusion bonded epoxy, polyurethane and polyurea coatings can be broadly categorized as organic coatings. Except for polyethylene encasement and asphaltic coating, the other coatings require a blast cleaned substrate and sufficient surface profile to achieve good adhesion to the substrate.

Polyethylene Encasement

Polyethylene encasement is the most widely used method of protecting ductile iron pipe in a corrosive underground environment. The process involves wrapping the pipe with a tube or sheet of polyethylene film during installation in the ground. The polyethylene acts as an unbonded film that prevents direct contact of the pipe with the soil. It also reduces moisture which in turn restricts electrolyte formation. ANSI/AWWA C105 describes materials and installation procedures for polyethylene encasement to be applied to underground installations of ductile-iron pipe, including fittings, valves, and other appurtenances. Polyethylene encasement consists of either 8 mil linear low-density (LLD) polyethylene film or 4 mil high-density cross-laminated (HDCL) polyethylene. (Ref: Polyethylene Encasement, Revised 2-12, Ductile Iron Pipe Research Association)

(Photo ref: Polyethylene Encasement, Revised 2-12, Ductile Iron Pipe Research Association)

Asphaltic Coating

Unless otherwise specified, ductile iron pipe manufactured in accordance with ANSI/AWWA C151/A21.51, “Ductile-Iron Pipe, Centrifugally Cast, for Water,” is supplied with an asphaltic coating approximately 1-mil thick. This coating, which is applied for aesthetic reasons, is used under normal conditions for both above and below ground applications. Typically, it is used in aboveground applications such as pump stations, bridge crossings, and pipe on supports, installations. For special aboveground conditions, other types of coatings as described earlier – epoxies, for example – are available.

Epoxy

There are a variety of epoxy coatings that can be used for exterior underground protection. Polyamide epoxies are known for having better flexibility and water resistance, while amine cured epoxies typically have better chemical resistance. These properties make polyamide epoxies a more logical choice for providing water resistance. Polyamide epoxies are typically applied in one to three coats at an application thickness of several mils per coat. Thicker film epoxy coatings, such as those based on epoxy phenol novolac resins, generally offer better chemical resistance.

Fusion Bonded Epoxy

Fusion bonded epoxy (FBE) coatings are powder coatings that are heated upon application to fuse the powder material into a continuous coating and bond it to the iron substrate. The powder application is a shop operation that is accomplished by an electrostatic spray or fluidized bed process. The application thickness typically ranges from 10 to 40 mils. Typical pipeline applications include internal and external coatings for natural gas, petroleum, water and sewage, as well as pipe systems for refineries, petrochemical plants, power plants and paper mills. ANSI/AWWA C116, “Protective Fusion-Bonded Epoxy Coatings for the Interior and Exterior Surfaces of Ductile-Iron and Gray-Iron Fittings,” describes protective fusion-bonded epoxy coatings for the interior and exterior surfaces of ductile-iron and gray-iron fittings used for water, wastewater, and reclaimed water systems. The standard describes the material, application, and performance requirements for these coatings.

100% Solids Rigid Polyurethanes

Rigid polyurethanes for ductile iron pipe – as opposed to elastomeric coatings – are high-build 100% solids coatings applied by plural component spray equipment. These coatings offer excellent chemical and abrasion resistance and see use in the petroleum, water and wastewater industries. Polyurethanes for buried service are typically aromatic materials. Since ultraviolet/sun exposure, which is detrimental to aromatics is not anticipated, aromatics generally provide better performance in the underground service environment. For above ground applications, coating formulations use aliphatic polyurethanes rather than aromatic. Typical application thickness is 15 to 30 mils to a blast cleaned substrate. (Ref: Guan, S.W., “100% Solids Rigid Polyurethane Coatings Technology and Its Application on Pipeline Corrosion Protection,” ASCE, Pipelines 2003)

Elastomeric Polyurethane, Polyurea and Hybrids

Polyurethane and polyurea based elastomeric coatings are multi-component materials generally requiring application by plural-component spray equipment. These types of coatings are relatively impermeable to moisture and provide excellent chemical and solvent resistance. The coatings are typically 100% or very high solids materials that are applied in a single coat that cures very rapidly. While fast cure can be desirable for handling, the rapid curing can also present problems with the coating adequately wetting the surface, potentially leading to poor adhesion.

Polyurethanes are formed by the reaction between an isocyanate and a polyol, such as polyester, polyacrylate, or polyether, whereas polyurea coatings are formed by the reaction between an isocyanate and an amine. One advantage with polyurea is that the rapid curing reaction is not affected by moisture or temperature, which can negatively affect the cure of polyurethanes. The cure is so rapid for polyureas however, that the problem with achieving adequate surface wetting can be more pronounced compared to polyurethane, sometimes preventing the successful use of polyurea coatings.

Hybrid polyurethane/polyurea coatings, formed using a combination of the two resin types, potentially offer a solution in combining the best features of each coating type. Advantages of elastomeric polyurethanes are excellent flexibility and elongation, impact resistance and abrasion resistance. Disadvantages include a relatively low resistance to acids, alkalis, and solvents.

Single-component elastomeric polyurethane coatings can also be formulated using moisture-curing polyurethane resins. These resins contain functional groups that react with moisture in the environment to form the cured coating film. Moisture-curing polyurethanes offer nearly the same performance properties as multi- component polyurethanes with the obvious advantage of a single pack product that does not need plural-component equipment for application.

Tape Wraps

Tape wrap coatings are typically used on joints between pipe sections, and on fittings and components that are irregular in shape. Cold applied tapes comprise one category of wraps. These materials have a wide range of composition and adhesive characteristics and are corrosion-resistant in many environments and temperatures. Another option for joints is installation of a heat shrinkable tubular sleeve. These sleeves typically consist of a polyolefin backing coated with a heat sensitive adhesive that bonds the sleeve tightly to the substrate. Some manufacturers also supplement the material with tools to aid in the ease of installation.

Thermal Spray

Thermally sprayed zinc (Zn) and zinc/aluminum (Zn/Al) coating has been increasingly applied to ductile iron pipe where a high degree of protection is required. The metal coating is applied by “thermal spray” where the metal, in wire or powder form, is heated, liquefied, and sprayed onto the substrate. Thermal spray coatings provide galvanic protection to the iron and are very durable and abrasion resistant. The typical compositions of the metal coating is 99.9% zinc or 85% zinc/15% aluminum. The substrate must be blast cleaned to achieve a deep and angular profile, with the thermal spray coating typically applied from 8 to 14 mils. (Ref: Gulec A., Cevher O., Ustel F., Turk A., Akinci A., “Comparison of Thermal-Sprayed Coatings for Ductile Iron Pipe,” Materials Performance, Vol. 50, No. 2.)

Interior Coatings and Linings for Cast Iron/Ductile Iron in Underground Service

Coatings or linings for the interior of iron pipe include epoxy, fusion bonded epoxy, polyurethane and polyurea coatings. An additional interior lining that sees common use is cement-mortar. Specialty linings may also be used for certain applications.

Cement-Mortar Linings

Cement-mortar linings are primarily used in water mains. These linings were first used in the 1920’s and are applied in a shop using a centrifugal process or projection method to produce a uniform thickness and smooth surface. An industry specification for the lining is provided by ANSI/AWWA C104, “Cement-Mortar Lining for Ductile Iron Pipe and Fittings for Water.” This standard provides the minimum requirements for shop-applied, cement–mortar linings for ductile-iron pipe and ductile-iron and gray-iron fittings for potable water, raw water, wastewater, and reclaimed water systems, including requirements for cement, sand, water, and mortar; surface of pipe and fittings for lining; method and thickness of lining; and curing. An optional seal coat may be applied to the cement lining. The seal coat minimizes moisture loss during hydration of the cement which controls its cure. The seal coat also protects the cement from leaching in soft, aggressive waters. A limitation of the seal coat is that water temperature should not exceed 150°F due to softening at higher temperatures. The thickness of the cement lining should not be less than 1/16-inch for 3 to 12-inch pipe, 3/32-inch for 14 to 24-inch pipe and 1/8-inch for 30 to 64-inch pipe. (Ref: “Corrosion Control, Cement-Mortar Linings for Ductile Iron Pipe,” Ductile Iron Pipe Research Association, March 2016)

Epoxy, Fusion Bonded Epoxy, Polyurethane and Polyurea

Epoxy, Fusion Bonded Epoxy, Polyurethane and Polyurea coatings are the same materials described for exterior buried pipe. These coatings require a blast cleaned substrate and sufficient surface profile to achieve good adhesion to the substrate. The specific type of coating selected should correspond to the interior pipe service conditions.

Specialty Linings

A variety of specialty linings may be used for certain applications such as interior pipe environments with high solids material flow. Glass/porcelain enamel is one example used in wastewater applications. The slick surface of this lining minimizes solids build up on pipe walls and provides good abrasion resistance. Another example is a ceramic modified-epoxy lining with similar properties.

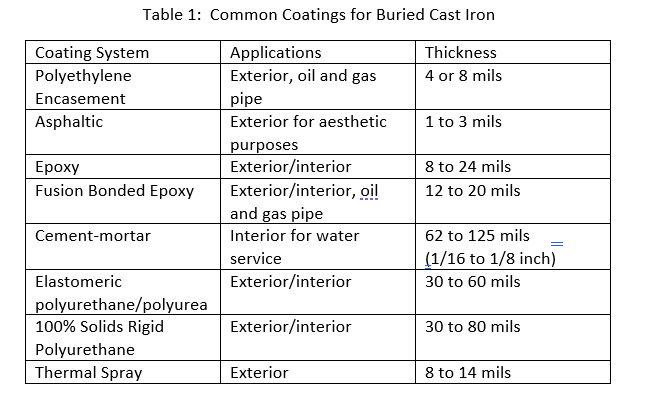

A summary of common coatings used for buried cast iron is provided in Table 1.

Conclusion – Different coating systems can be applied to cast iron/ductile in the shop or field, both for beautification and for protection. The systems should be selected based on their ability to perform in the service environment and provide the appropriate aesthetics, if required.

Topics in this cast iron/ductile iron series:

Topic 1 – Preparation of cast iron/ductile iron for painting

Topic 2 – Coatings for cast iron/ductile iron

Topic 3 – Inspection of surface preparation and coating application

Written by KTA’s Jay Helsel, PE

Nice paper, especially in times when the Energy Crisis is taking on more burden than material costs, this could open the door to new application of technology on pure business case basis.