Introduction

Occupational exposure to respirable crystalline silica in the coatings industry may occur during, or while working alongside dust-producing operations involving a concrete substrate, while using sand as an abrasive (silica may be present in the abrasive), or as a component of the coating (silica may be an extender used in coatings). Operations using sand or products containing silica can result in worker inhalation of small (respirable) crystalline silica particles that become airborne.

Possible Health effects from silica exposures include:

- Silicosis, a disabling, non-reversible and sometimes fatal lung disease;

- Other non-malignant respiratory diseases, such as chronic bronchitis;

- Lung cancer;

- Kidney disease, including nephritis and end-stage renal disease; and

- Auto-immune disorders and cardiovascular disease.

OSHA Action Level and Permissible Exposure Limit

Each employer is responsible for ensuring that no employee is exposed to respirable crystalline silica above OSHA’s permissible exposure limit (PEL) of 50 micrograms per cubic meter (µg/m3) of air averaged over an 8-hour work shift (time-weighted average, or TWA). OSHA has defined the Action Level for respirable crystalline silica at 25 µg/m3 of air TWA. Once employee exposure reaches the Action Level the employer is required to implement engineering controls, administrative controls, then personal protective equipment in order to comply with the OSHA’s Respirable Crystalline Silica Regulations.

Each employer is responsible for ensuring that no employee is exposed to respirable crystalline silica above OSHA’s permissible exposure limit (PEL) of 50 micrograms per cubic meter (µg/m3) of air averaged over an 8-hour work shift (time-weighted average, or TWA). OSHA has defined the Action Level for respirable crystalline silica at 25 µg/m3 of air TWA. Once employee exposure reaches the Action Level the employer is required to implement engineering controls, administrative controls, then personal protective equipment in order to comply with the OSHA’s Respirable Crystalline Silica Regulations.

What do I need to do to comply with OSHA?

Compliance with OSHA’s Respirable Crystalline Silica regulations includes development of a written exposure control program, personal air monitoring within the worker’s breathing zone, medical evaluations, and training.

Compliance with OSHA’s Respirable Crystalline Silica regulations includes development of a written exposure control program, personal air monitoring within the worker’s breathing zone, medical evaluations, and training.

The written exposure control program must contain at least the following information:

- A description of the tasks in the workplace that involve exposure to respirable crystalline silica;

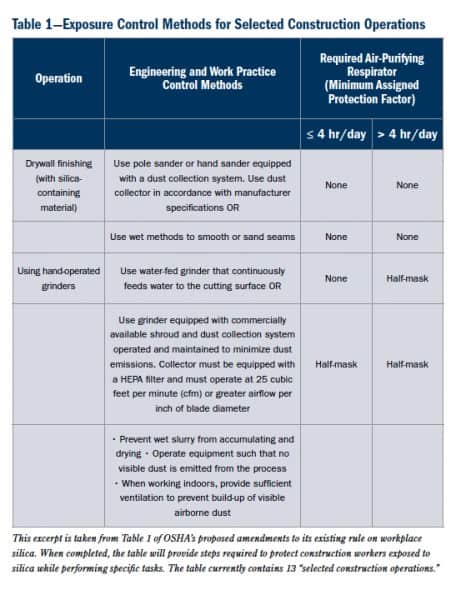

- A statement that the employer fully and properly implements the engineering controls, work practices, and respiratory protection specified for the task on Table 1A or;

- A description of the engineering controls, work practices, and respiratory protection that will be used to limit employee exposure to respirable crystalline silica for each task;

- A description of the housekeeping measures used to limit employee exposure to respirable crystalline silica; and

- A description of the procedures used to restrict access to work areas, when necessary, to minimize the number of employees exposed to respirable crystalline silica and their level of exposure, including exposures generated by other employers or sole proprietors.

The employer is required to review and evaluate the exposure control plan at least annually, and update it as necessary. The written exposure control plan must be readily available for examination and copying upon request, to each employee, their designated representatives, and OSHA. A designated competent person is required to make frequent and regular inspections of job sites, and to implement the written exposure control plan.

Air monitoring

An assessment of the exposure level of employees who may reasonably be expected to be exposed to respirable crystalline silica at or above the Action Level is required to be performed in accordance with either performance options or scheduled monitoring. Performance monitoring consists of assessing the 8-hour TWA exposure for each employee based on any combination of air monitoring data or objective data sufficient to accurately characterize the employee exposures to respirable crystalline silica.

The scheduled monitoring option requires the employer to perform initial monitoring to assess the 8-hour TWA exposure for each employee based on one or more personal breathing zone air samples that reflect the exposures of employees on each shift, for each job classification, in each work area. Where several employees perform the same tasks on the same shift and in the same work area, the employer may sample representative employees to meet this requirement.

If representative sampling is employed, the employer must sample the employee(s) who are expected to have the highest exposure to respirable crystalline silica. When initial monitoring indicates that employee exposures are below the action level, monitoring for those employees may be discontinued. When the most recent exposure monitoring indicates an employee exposure at or above the Action Level, and below the PEL monitoring for that employee must be repeated within six months. When the most recent monitoring indicates that employee exposure is above the PEL, monitoring for that employee must be repeated within three months. Where a follow up (non-initial) exposure monitoring indicates that the employee exposure is below the Action Level, the employer shall repeat such monitoring within six months of the most recent monitoring until two consecutive measurements, taken seven or more days apart, are below the Action Level, at which time monitoring may be discontinued for those employees.

Whenever a change in production, process, control equipment, personnel, or work practices may reasonably be expected to result in new or additional exposures at or above the action level, or when there is reason to believe that new or additional exposures at or above the action level have occurred employee exposures are required to be reassessed. Samples for respirable crystalline silica are required to be evaluated by a laboratory that is accredited to ANSI/ISO/IEC Standard 17025:2005.

Medical Surveillance

Medical surveillance is to be provided to employees exposed to respirable crystalline silica at or above the action level of 25 µg/m3 at no cost to the employee, and at a reasonable time and place. An initial (baseline) medical examination must be conducted within 30 days after the initial assignment, unless the employee has received a medical examination within the last three years.

Medical exams must include:

- Medical and work history emphasizing past, present and anticipated exposures to respirable crystalline silica, or other respiratory system affecting agents.

- History of respiratory system dysfunction or disease

- Physical exam that focuses on the respiratory system

- A chest X-ray

- Latent Tuberculosis infection testing

- Pulmonary function test

- Medical evaluation for respiratory protection in accordance with the employers Respiratory Protection Program.

All medical evaluations are to be perform by a Physician or a Licensed Health Care Provider (PLHCP), with results provided to the employee and employer within 30 days of the medical examination.

Training

Each employee exposed to respirable crystalline silica is required to be trained prior to an initial assignment, and when there is a change in the process. The training should include:

- Health hazards associated with exposure to respirable crystalline silica;

- The tasks with potential exposure to respirable crystalline silica;

- The engineering controls, work practices, and respirators to be used;

- Content of the companies Respirable Crystalline Silica Policy;

- Information pertaining to Silicosis;

- Identity of the competent person; and

- Purpose and description of the employer’s medical surveillance program

If you have any questions or would like to request testing related to this article, feel free to reach out to us at 1-800-245-6379 or Click Here.