Independent verification of coating system performance based on laboratory testing and/or field exposure is a critical component to coating system selection. For a given coating system, there may be six or eight manufacturers. It is not safe to assume that all coating systems within a given generic category are created equal. Therefore, careful evaluation of coating system performance prior to full-scale field application can be used to determine which of the candidate systems will perform the best. These performance evaluations can be facility-specific, industry-specific or coating type-specific. Each of these evaluation methods and their inherent advantages and limitations are described in this article.

Facility-Specific Performance Evaluations

Many facility owners (particularly chemical plants) cannot rely 100% on industry-generated performance data, since it may be too generalized and not address specific service environments or upset conditions unique to a given facility. And few will rely on coating manufacturer-generated data because of perceived bias. Therefore, many facilities establish their own coating/lining system performance testing program that often includes actual plant site exposure of candidate systems applied to test panels, or test patch application of candidate coatings systems to the actual structure. The advantage of this type of performance evaluation is that if designed properly, it can closely mimic the actual service conditions of the facility. However, if the testing is not based on existing ASTM test procedures and custom testing facilities or equipment is required, the testing may be expensive and it may be difficult to locate laboratories that can generate the data.

Industry-Specific Performance Evaluations

An industry-specific coating performance evaluation program generates performance data based on testing that represents (as close as possible) the service environment of that industry. Once the data is generated, it can be uploaded into a central database so that all member agencies in that industry can access the information and establish their own qualified products list. Examples of industries employing this type of program include publicly owned wastewater treatment facilities and departments of transportation.

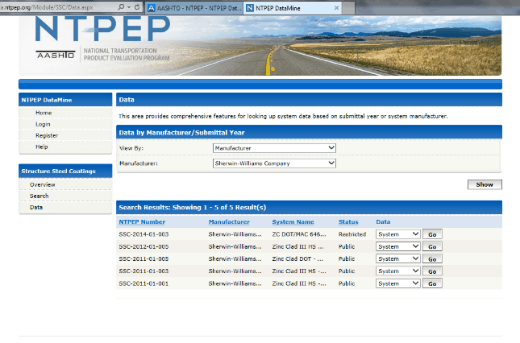

The American Association of State Highway and Transportation Officials (AASHTO) oversees a material testing organization known as NTPEP (National Transportation Product Evaluation Program). NTPEP is comprised of highway safety and construction materials Project Panels.  These Panels are made up of state highway agency personnel, with the objective of providing quality and responsive engineering for the testing and evaluation of products, materials, and devices that are commonly used by the AASHTO member departments of transportation. In 1997, the Structural Steel Coatings (SSC) Panel was created to develop a standard specification, a corresponding project work plan and a reporting system for testing of industrial coating systems for use on bridge and highway structures. Data is generated by pre-qualified independent testing laboratories, then uploaded to a central database known as Datamine for DOT access. All testing is paid for by the coating manufacturer. A sister program designed to evaluate coating systems applied to concrete was established in 2010.

These Panels are made up of state highway agency personnel, with the objective of providing quality and responsive engineering for the testing and evaluation of products, materials, and devices that are commonly used by the AASHTO member departments of transportation. In 1997, the Structural Steel Coatings (SSC) Panel was created to develop a standard specification, a corresponding project work plan and a reporting system for testing of industrial coating systems for use on bridge and highway structures. Data is generated by pre-qualified independent testing laboratories, then uploaded to a central database known as Datamine for DOT access. All testing is paid for by the coating manufacturer. A sister program designed to evaluate coating systems applied to concrete was established in 2010.

The advantage of this type of performance evaluation is that many agencies within a given industry can access performance data with little or no associated costs. Limitations include keeping the database current as new coating systems come to market, the time associated with generating the performance data (AASHTO NTPEP SSC requires approximately 10 months), and applying the same performance data for a coating system that will be used on a bridge structure in northern Minnesota and on a bridge in Phoenix, Arizona – two very different service environments.

Coating System-Specific Performance Evaluations

The final method that may be used to evaluate the performance of a protective coating/lining system is employing an industry standard testing procedure designed specifically for a type of coating. An example of this type of performance evaluation is SSPC’s Paint Specification No. 36, Two-Component Weatherable Aliphatic Polyurethane Topcoat, Performance-Based. These types

The advantage to this type of performance testing is that it establishes minimum performance requirements for a given type of coating that can be readily adopted by many industries. There are no significant limitations to this type of performance evaluation.

Employing Multiple Performance Evaluation Methods

Some facility owners and agencies may choose to employ a combination of the performance evaluation methods listed above. For example, a bridge owner may subscribe to the AASHTO NTPEP SSC Datamine (industry-specific performance evaluation) and may also suspend or mount racks of test panels containing candidate coating systems from a bridge structure (facility-specific performance evaluation) and rate them every 6 months for corrosion and/or aesthetics. Alternatively test patches of candidate coating systems can be installed on the actual structures (per ASTM D5064, Standard Practice for Conducting a Patch Test to Assess Coating Compatibility) and evaluated after a given number of thermal cycles (as appropriate) for adhesion, resistance to corrosion undercutting, color and gloss retention, graffiti resistance or other properties of interest.