Introduction – Aluminum and aluminum alloys exhibit good corrosion resistance by virtue of a layer of aluminum oxide that forms on the surface.

While aluminum is often not coated because of its good corrosion resistance properties, there are occasions when coatings are applied to provide added protection in given environments (e.g., when the pH is below 4 or higher than 9) or for aesthetics. When aluminum is coated, the method(s) of surface preparation must be suitable for the selected coatings. The type of surface preparation will also be influenced by the location in which the work is done; in a coating plant, an aluminum fabrication shop, or in the field. The form of the aluminum (sheet, extruded or cast) and whether the aluminum was previously coated will also impact the method of preparation and the coatings to be applied.

Plant and Shop Surface Preparation and Conversion Coatings

Aluminum is often roll formed into sheets or extruded into shapes with a specific cross-sectional profile due to the high throughput of these manufacturing processes. Aluminum sheet and extrusions lend themselves to high-speed coating processes which include surface preparations steps such as cleaning and conversion coating as part of the overall process.

Cleaning removes oils, greases and dirt that would interfere with the conversion coating and painting processes. The cleaning solutions are generally caustic to break down fats and contain detergents to help with wetting and the suspension of soils. The cleaning residues must be thoroughly rinsed from the surface prior to the application of conversion coating. Conversion coating is a process in which the existing oxide is replaced with a thin mixed metal oxide that provides improved corrosion resistance and a base for adhesion of conversion coatings. Historically, conversion coatings have been based on hexavalent chromium (Cr6+) but they are being replaced due to environmental and worker health concerns. Trivalent chromium (Cr3+) based conversion coatings have been successful replacements in specific applications. Several non-Cr conversion coatings have been developed including those based on zirconates, titanates, cerium, silanes and organics. These non-Cr chemistries are rapidly being adopted for use in a range of industries.

Aluminum fabrication shops may use automated chemical surface preparation were the individual pieces are hung on a conveyor belt and dipped into each of the process baths. In other instances, this is not practical due to the wide range of non-standard part shapes. In this case light abrasive blast cleaning, as discussed in the next section, is used as an alternative to chemical pretreatments.

Field Surface Preparation

Preparation of bare aluminum and repair or replacement of existing coatings in the field requires surface preparation methods that are mobile. The extent of cleaning required will be dictated by the condition of the existing coating or the substrate. The surface should be cleaned prior to coating removal regardless of the method. Detergent cleaning will remove debris, particulate and water-soluble salts while solvent washing is required to remove oils, greases and waxes that are not water-soluble. Commonly used solvents include acetone, ketones and mineral spirits and can be applied by clean rags or paper towels. The surface cleanliness should be verified by a water break test (ASTM F22, Standard Test Method for Hydrophobic Surface Films by the Water-Break Test) or the atomizer test (ASTM F21, Standard Test Method for Hydrophobic Surface Films by the Atomizer Test).

Hand or power tool cleaning can be used to remove loose or poorly adhering coatings from relatively small areas and to degloss existing coatings to improve the adhesion of subsequent coats. For larger areas blast cleaning is a more efficient means of preparation.

SSPC-SP-16, Brush-Off Blast Cleaning of Coated and Uncoated Galvanized Steel, Stainless Steels, and Non-Ferrous Metals, and SSPC-SP17, Thorough Abrasive Blast Cleaning of Non-Ferrous Metals, provide a wealth of information on blast cleaning. Both methods provide surface cleanliness requirements for blast cleaning but differ in that SP-16 covers brush-off blasting and allows for intact, tightly adherent coating to remain, which must be roughened. If a coating cannot be lifted with a dull putty knife it is considered tightly adherent. This standard would be applicable for surface preparation prior to repair coating where most of the existing coating was in good condition. SP-17, in contrast, requires complete removal of the coating and random color variations must be limited to less than 5% of each unit area of the surface (a unit area is 9 square inches in size). This specification would be applicable for previously uncoated surfaces or when complete coating removal and recoating is required. Both standards require solvent cleaning in accordance with SSPC-SP-1, Solvent Cleaning, and removal of surface imperfections including sharp edges, crevices, weld porosities and laminations prior to coating removal. SP-16 requires a minimum profile of 0.75 mils on the bare metal, and SP 17 requires a dense and uniform surface profile with a depth appropriate for the coating.

Blast cleaning of aluminum requires special considerations. Low blasting pressure should be used to prevent over-roughening or deformation of thinner workpieces. Abrasive embedment is always a possibility during blast cleaning. Non-metallic abrasives should be used to prevent galvanic corrosion which can occur when aluminum is in electrical contact with metals having a more positive corrosion potential. Abrasives such as aluminum oxide, garnet, crushed glass or encapsulated abrasive media perform well for cleaning and producing a profile. Softer abrasives such as glass beads, baking soda, dry ice or agricultural abrasives (walnut shells, corn cobs and peach pits) can remove the coating without generating a significant surface profile.

The creation of a project mock-up for field work is recommended when specifying SSPC-SP16 and is mandatory for SSPC-SP17 because there are no visual standards to address the cleanliness and uniform roughening of aluminum. The mock-up serves as a job reference standard of the required degree of surface preparation and should be representative of the material being cleaned.

Dry blast cleaning may not be appropriate where dust generation is of concern. In these instances, vacuum blast cleaning, wet abrasive blast cleaning, or high pressure waterjetting with or without injection of fine abrasives should be considered.

Coatings for Aluminum

A variety of coating materials are available for application to aluminum. A few are described below:

Anodizing – As noted in the introduction, aluminum and aluminum alloys are often not painted because they exhibit good corrosion resistance by virtue of a layer of aluminum oxide that forms on the surface. If the service environment is suitable for bare aluminum, this natural resistance can be enhanced by increasing the thickness of the aluminum oxide layer through a process called anodizing. The surface can also be colored at the same time. The Master Painters Institute (MPI) Glossary defines Anodized Aluminum as “Aluminum onto which a protective, often colored, layer of oxide has been placed by electroplating.” Anodizing is performed in specialized facilities. Anodized aluminum should be sealed to get the maximum corrosion resistance.

Coil Coating – Coil coating applies a protective and decorative film to aluminum coil in an automated process that performed in specialized facilities. The aluminum substrate, provided to the shop in coil form, is automatically cleaned, pretreated (conversion coating), primed, painted, and baked. The coated coil is subsequently cut or formed into different shapes for its end use. Coatings applied to the coil are acrylic, epoxy, polyester, polyurethane, polyvinylidene fluoride, and others. The coating systems are applied to lesser thicknesses than their sprayapplied counterparts, generally a mil or two in total. The National Coil Coating Association (NCCA) provides a great deal of technical information related to coil coatings.

Power Coating – Powder coating is done in shops. Coating in power form is sprayed onto the pieces by electrostatic spray, followed by heating which melts the powder to create a monolithic film. The most common powder coating is epoxy. The Powder Coating Institute (PCI) provides educational material regarding powder coatings.

AAMA (Architectural Aluminum Metal Manufacturers Association) coating standards – AAMA provides three different coating standards for shop application to aluminum extrusions and panels with emphasis on color and gloss retention:

- AAMA 2603, Voluntary Specification, Performance Requirements and Test Procedures for Pigmented Organic Coatings on Aluminum Extrusions and Panels. The AAMA 2603 performance requirements are the least rigorous of the three AAMA standards and are designed to identify products that will provide and maintain a good level of performance and general appearance. Coatings in this category are typically for interior use and include baked enamels (polyesters and acrylics).

- AAMA 2604, Voluntary Specification, Performance Requirements and Test Procedures for High Performance Organic Coatings on Aluminum Extrusions and Panels. The AAMA 2604 performance requirements are in the middle of the three AAMA standards and are designed to identify products that will provide and maintain a high level of performance and general appearance. Coatings in this category typically include silicone-modified polyesters and 50% polyvinylidene fluoride (PVDF).

- AAMA 2605, Voluntary Specification, Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels. The AAMA 2605 performance requirements are the most rigorous of the three AAMA standards and are designed to identify products that provide and maintain a superior level of performance and general appearance. Coatings in this category typically include 70% polyvinylidene fluoride (PVDF).

Liquid Coatings – Many of the coatings applied to steel substrates can be applied to properly prepared aluminum, including acrylic, epoxy, polyester, polyurethane, polysiloxane, and fluoropolymers. However, zinc primers, which are commonly used on steel, are not used on aluminum. One or two coats of the liquid coating are applied depending on the service environment, durability needed, and whether a conversion coating has already been applied. When surfaces are exposed to sunlight, epoxy should not be used alone as it will chalk. Epoxy should be topcoated with other coatings such as polyurethane, polysiloxane, or fluoropolymers. If a coating is already present on the aluminum, the new coating must be compatible with the existing. If there are questions regarding the existing coating type and compatibility, coatings professionals and coating manufacturers can help.

When overcoating existing coatings, especially factory finishes, it is advisable to apply test patches of the candidate coatings to confirm that the surface preparation is adequate, and the new coating adheres properly to the existing material. Test patches can also be used to compare coating adhesion over different methods and types of preparation. The longer the test patch is exposed prior to evaluation, the better, but the evaluation should not take place before the published curing times for the newly applied material have been observed. Evaluations include testing adhesion and visual inspections for blisters, pinholes, fisheyes, peeling and other film defects. ASTM D5064, Standard Practice for Conducting a Patch Test to Assess Coating Compatibility provides guidance for installing and evaluating test patches.

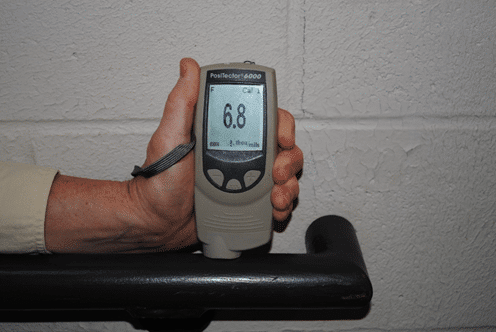

Measuring Coating Thickness – The selected coatings must be applied to the manufacturer’s recommended dry film thickness (DFT) to achieve the desired performance. It is good practice for applicators to use wet film thickness (WFT) gages to verify sufficient material is being applied to achieve the specified DFT range. Measuring the WFT of a coating allows the applicator to adjust the application technique to apply the correct amount of coating.

Dry film thickness is measured according to SSPC-PA 2, Procedure for Determining Conformance to Dry Coating Thickness Requirements. This standard is widely used in the industrial coatings industry to establish the frequency of measurements and to determine acceptability. ASTM D7091, Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals, describes three operational steps to be performed before measuring the thickness to help assure the reliability of the measurements:

- gage calibration (performed by the gage manufacturer or certified laboratory at prescribed intervals, typically yearly)

- verification of gage accuracy (performed by the gage user during each period of use)

- gage adjustment (performed by the gage user during each period of use)

These steps are incorporated by reference in SSPC-PA 2 and must be completed before measuring the coating thickness.

Conclusion – Aluminum can be successfully coated in the shop and field provided the surface is adequately prepared to assure proper adhesion of the applied coating. The appropriate surface preparation method should be selected for use in a coating plant, an aluminum fabrication shop or in the field, as applicable. A number of coating systems can be applied to aluminum. Specialized systems include powder coating and coal coating. Most coatings applied to steel can also be used on aluminum. Regardless the coating being applied, the dry film thickness should be measured to confirm that the manufacturer’s recommended thickness is being achieved.