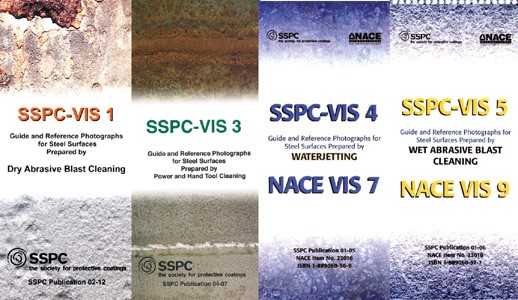

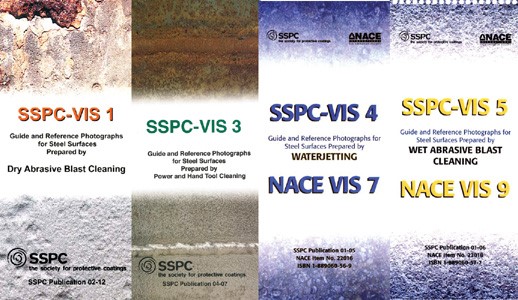

SSPC has published four visual guides that depict the different degrees of cleaning for dry and wet abrasive blast cleaning, water jetting, and hand/power tool cleaning. Two of the four were prepared jointly with NACE International (Figure 1).

The guides are:

- SSPC-VIS 1, Guide and Reference Photographs for Steel Surfaces Prepared by Dry Abrasive Blast Cleaning

- SSPC-VIS 3, Guide and Reference Photographs for Steel Surfaces Prepared by Power and Hand Tool Cleaning

- SSPC-VIS 4/NACE VIS 7, Guide and Reference Photographs for Steel Surfaces Prepared by Waterjetting

- SSPC-VIS 5/NACE VIS 9, Guide and Reference Photographs for Steel Surfaces Prepared by Wet Abrasive Blast Cleaning

The photographs in the guides depict the appearance of surfaces both prior to and after cleaning. This article describes the use of the guides, using SSPC-VIS 1 as the example.

Step 1 – The first step in using any of the guides is to identify the photographs that most closely depict the initial condition of the steel that will be cleaned. The appearance of the same degree of cleaning (e.g., SSPC-SP10, Near White) can appear different depending on the initial condition of the steel prior to cleaning. Because of this, it is important to first select the photographs that most closely approximate the initial condition.

For SSPC-VIS 1, seven photographs depict seven initial conditions (4 unpainted and 3 previously painted):

Unpainted initial conditions:

- Condition A – Intact mill scale (Figure 2)

- Condition B – Rust and mill scale (Figure 2)

- Condition C – Totally rusted, with little -to-no visible pitting (Figure 3)

- Condition D – Totally rusted and pitted (Figure 3)

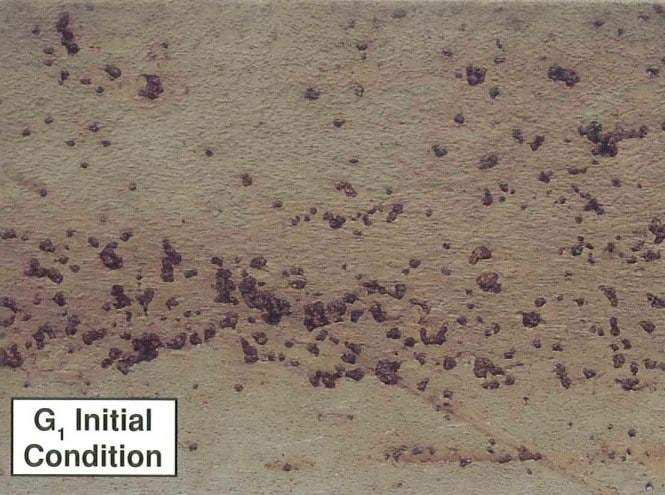

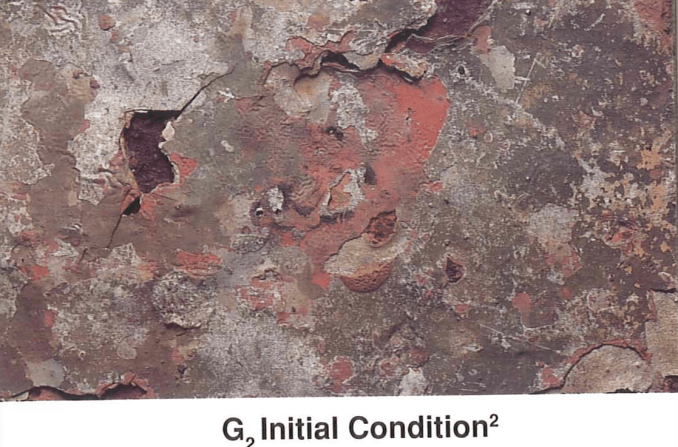

Painted initial conditions:

- Condition G1 – Aged coating with extensive pinpoint rusting (Figure 4)

- Condition G2 – Aged coating with moderating pitting (Figure 4)

- Condition G3 – Aged coating with severe pitting (Figure 4)

Step 2 – Turn to the section of the book that depicts the various degrees of cleaning over the selected initial condition. Four degrees of cleaning (SP7, SP6, SP10, SP5) are depicted for unpainted conditions A, B, C, and D. Five grades of cleaning (the same four plus SP14) are depicted for painted initial conditions G1, G2, and G3. Figure 5 shows four grades of blast cleaning over Condition B steel. Figure 6 shows the appearance of five grades of blast cleaning over an initial condition consisting of deteriorated paint with rust and pitting.

Step 3 – Once cleaning is underway, compare the photographs with the prepared surface to determine if the cleaning is compliant. Note that the reference photographs will not be identical to the prepared surface for many reasons. The initial conditions of the prepared steel are different than the initial conditions the reference photographs are based upon. Likewise, the abrasive used, depth of surface profile, and lighting will be different than the reference photos. The precise distribution of allowable material (staining) will also vary, leading to differences in appearance. It should be recognized that when the definitions indicate a percentage of staining remaining after cleaning, it is a maximum amount. For example, Commercial Blast allows staining on up to 33% of each unit area. Near White allows staining on up to 5%. Based on these thresholds, staining between 6% and 33% would all be considered to represent Commercial Blast. With such a wide variation of staining allowed, it is not surprising that the photographs will never look identical to a Commercial Blast cleaned surface since the amount of staining can vary quite a bit. Accordingly, it is important to use the photos as a guide for the appearance rather than as an absolute comparison. It is helpful to compare the surface with all of the photographs in the series to approximate the appearance (Figure 7).

Finally, it must also be recognized that the written text of the standard takes precedence when determining cleanliness. The photos are secondary to the written word.