Physical Testing of Applied Coatings

Do you need Physical Testing of Applied Coatings?

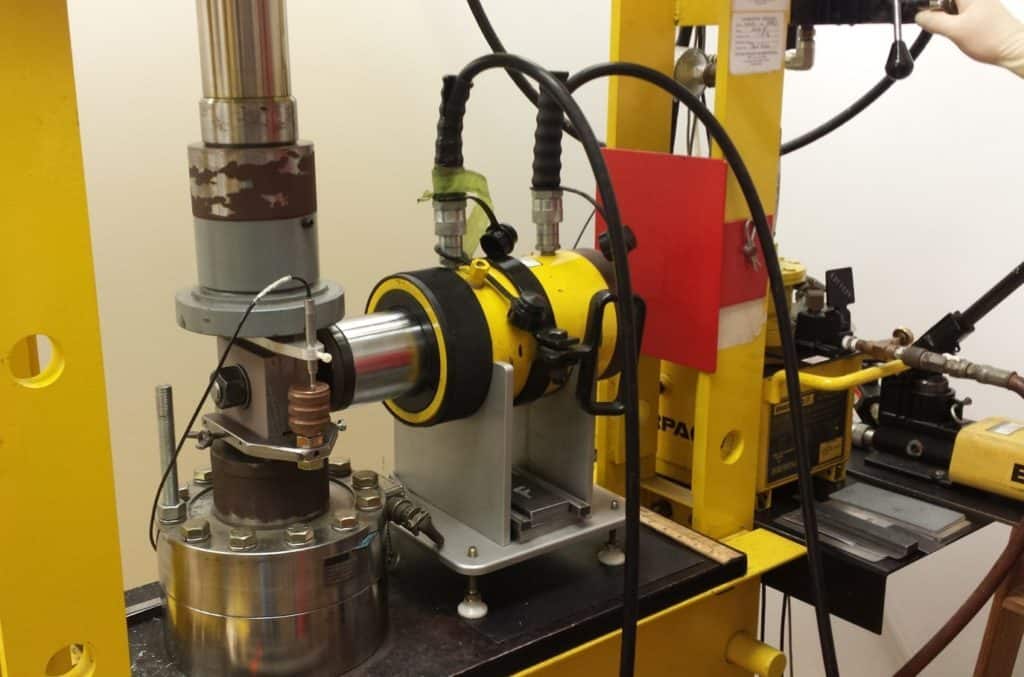

Industrial protective coatings and commercial paints are formulated to possess certain performance properties once they are applied. These characteristics often consist of both chemical and physical properties that are used to help determine the coating’s ability to perform well in a given service environment. Evaluating the physical properties of coatings (often applied to test panels) helps to verify and predict performance (or lack of performance) prior to full scale application. However, when this performance data is generated by the coating manufacturer, it is often perceived as being biased. KTA is independent of facility owners, painting contractors and coating manufacturers, enabling any of these parties to have coatings and/or coating systems independently evaluated for performance properties.

Our Physical Testing of Applied Coatings offerings include (but are not limited to):

Why Use KTA for Physical Properties Testing?

We are active members of ASTM subcommittees D01.21, D01.23, D01.46, D01.48 and G01.05 that are responsible for writing and maintaining the coatings testing standards. Don’t trust your project or your coatings to just any testing laboratory; choose KTA. We specialize in coatings testing and we offer a wealth of industry knowledge and decades of paint and protective coatings experience to you and your company. Let us help you design a test regime that focuses on the parameters that matter the most.

KTA’s Physical Testing of Applied Coatings Services Will Help Answer the Following:

How Can We Help?

Contact our Laboratory Services Group: