KTA’s Certified Coating Inspector Forum

Volume 5, Issue No. 1 – February 2026

William Corbett, Technical ConsultantAMPP Senior Certified Coating Inspector & Certified Protective Coating Specialist

KTA’s Certified Coating Inspector Forum is designed to provide professional development/continuing education on standards, inspection practices, new instruments, and other topics to help keep certified AMPP and FROSIO coating inspectors current. It represents the views of the author and KTA-Tator, Inc. It may or may not represent the views of AMPP: The Association for Materials Protection & Performance, even though SSPC, NACE, and AMPP standards are frequently referenced in the content.

Introduction

Late in 2025 I was instructing a basic coatings course for a steel fabrication shop to assist them in maintaining their AISC Complex Coatings Endorsement. They frequently are required to blast clean fabricated steel and apply zinc-rich primers and a variety of mid-coats and topcoats for buildings, stadiums, and other steel structures, some of which include architecturally exposed structural steel, or AESS. During the course they were commiserating about their experiences applying mid-coats and topcoats to zinc-rich primers; specifically, the problems they had with outgassing and subsequent formation of pinholes in the overcoats. With the help of the local coating manufacturer’s representative and some of their own ingenuity they had figured out how to prevent most of the outgassing problem. However, they did not understand why it was occurring in the first place. This issue of the KTA Certified Coating Inspector Forum describes why overcoats experience outgassing when applied to zinc-rich primers and explores ways to reduce the frequency of subsequent pinholing.

It is acknowledged that the means and methods of applying a continuous, uniform series of coating layers to create a resilient coating system is the applicator’s responsibility. However, understanding what causes various coating defects and the ways in which they may be prevented or resolved can greatly improve the value a certified coating inspector brings to any shop or job site.

Understanding Why Outgassing Occurs

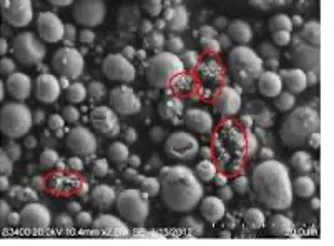

During the class we had a discussion of common shop-applied coatings, including their advantages, limitations, and inspection concerns. I took this opportunity to take a deeper dive into the subject of outgassing and why it occurs, since the participants raised the issue earlier in the course. Zinc-rich primers, especially the common inorganic variety (that contain a relatively small amount of silicate resin and a lot of zinc pigment) are porous. I like to use the analogy of a box containing baseballs, softballs, golf balls, etc. These various ball sizes represent the zinc powder shown in Figure 1.

Air is present between these different sized spheres in the dried film of a zinc primer (i.e., between the balls inside the box). When a mid-coat or topcoat is applied to the zinc primer, the air in the voids between the zinc particles becomes trapped and therefore slightly pressurized. In the process of releasing this pressure (the process of the air escaping), a hole is formed in the overcoat. This is known as outgassing. Unless the overcoat remains wet for a long time, the coating will not flow into and seal the pinhole, allowing it to remain in the newly applied coat. In extreme cases there can be hundreds or thousands of tiny pinholes in the overcoat, which is unacceptable. Note that outgassing can also occur when overcoating organic zinc-rich primers (containing epoxy or urethane resin); albeit to a much lesser extent since the porosity is lower due to a greater amount of resin in the dry film, compared to its inorganic counterpart.

Attempting to apply a repair coat over the pinholed coating to “fill” the pinholes is very difficult, as the air in the pinholes of the overcoat becomes trapped, recreating or mirroring the same problem.

Reducing the Opportunity for Outgassing

Most manufacturers of zinc-rich primers recommend a thinned mist coat be applied to the zinc-rich primer prior to application of the full coat. A mist coat is a very thin layer (typically 1-2 wet mils) of the overcoat applied prior to application of the full overcoat. A mist coat allows the entrapped air to release but is too thin to pinhole. This helps to seal the surface prior to application of the full coat, minimizing the formation of pinholes in the overcoat.

Thinning the mist coat to the maximum permissible (using the recommended thinner) helps the mist coat penetrate the zinc primer more effectively. However, due to volatile organic compound (VOC) regulations, the maximum amount of thinner allowed is restricted, potentially limiting the full effect that a mist coat can have. But this can be overcome by using an exempt thinner. If a compatible exempt thinner is listed on the product data sheet, if allowed by the specification, the applicator may consider “over-thinning” a mixture of the overcoat with the exempt thinner to use as the mist coat. This can be followed by the full coat application with a separate mix, thinned according to the manufacturer’s instructions. Naturally the Quality Control Inspector must document this process if used.

The steel fabricator I was instructing said that they decided to back-roll the mist coat after spraying it onto the zinc primer, which seemed to help (unknowingly, they were likely forcing the mist coat into the pores using roller pressure). While they indicated that it worked for them, this could be quite challenging to implement on large quantities of steel and could affect the aesthetics.

Thermal spray coatings applied by metallizing are also porous and frequently outgas when overcoated (unless a penetrating sealer is specified and applied), so application of a mist coat to release the entrapped air and seal the surface is frequently required when overcoating these types of protective coatings as well.

Summary

As trained and certified coating inspectors, we can increase our value when we truly understand the properties of protective coatings as well as the causes and remedies of various coating application defects. This issue of the KTA Certified Coating Inspector Forumdescribed why overcoats experience outgassing when applied to zinc-rich primers and explored ways to reduce the frequency of subsequent pinholing.