Permeability of Applied Paints & Coatings… Do I want a permeable coating or not?

The answer to the question posed is based on the substrate and the service environment. All paint and coatings are permeable to water, just to different degrees. A high resistance to permeability is likely desirable for lining applied to the interior of a tank or vessel; however, a paint system applied to the exterior of a masonry block building better be “breathable” to allow moisture in the block to escape. Otherwise blistering and peeling will likely occur.

What is water vapor transmission or WVT, the Water Vapor Permeance or WVP, and the Water Vapor Permeability?

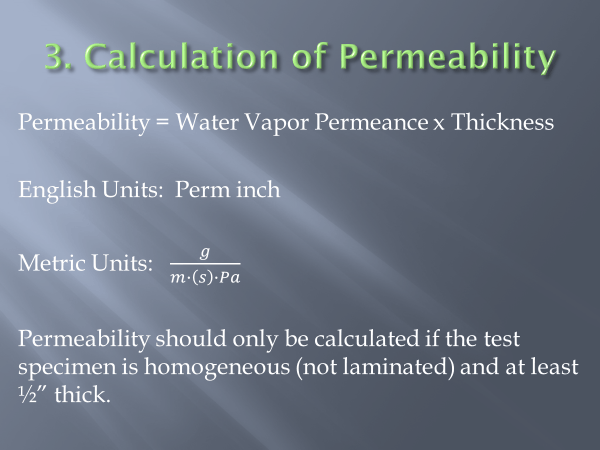

These three terms are used to describe how quickly water vapor diffuses through a solid material. The Water Vapor Permeance is often simply call the permeance, and the water vapor permeability is often simply called the permeability. The Water Vapor Transmission (WVT), permeance, and permeability are very closely related in that one is calculated from the other. First the WVT is determined. Then the permeance is calculated by dividing the WVT by the vapor pressure across the material under test. The permeability is calculated by multiplying the permeance by the thickness of the material.

What is water vapor?

Water vapor is the gaseous phase of water. In the gas phase, water molecules move very rapidly and are not bound together. Water vapor can be produced by the evaporation of water or the sublimation of ice or snow. It can also be produced by the boiling of water, but the steam that you can see coming out of your kettle technically is not water vapor. Water in the gas phase is invisible. The steam that you see consists of very small droplets of liquid water suspended in air.

How is the Water Vapor Transmission (WVT) measured?

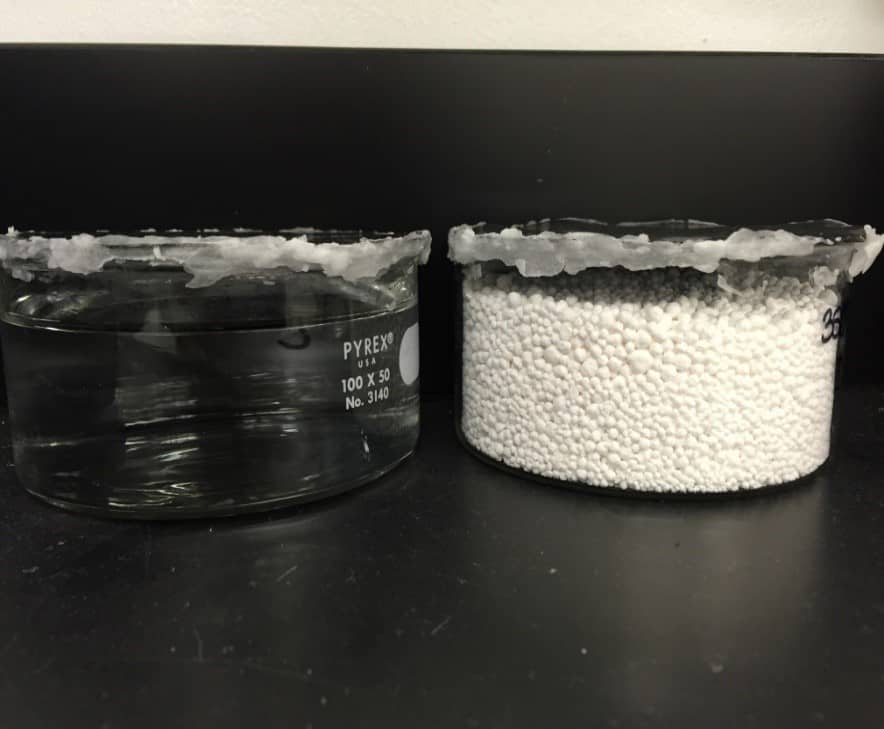

The fundamentals of the measurement of water vapor transmission in the laboratory are simple. WVT is determined by sealing a free film of the test material to the top of a container that is filled with water (left) or desiccant (right). If the container is filled with water, the method is called the wet cup method or the water method. If the container is filled with desiccant, the method is called the dry cup method or the desiccant method. Essentially, the test determines how much vapor is lost through the film in the wet cup method or how much vapor the desiccant attracts or draws through the film for the dry cup method.

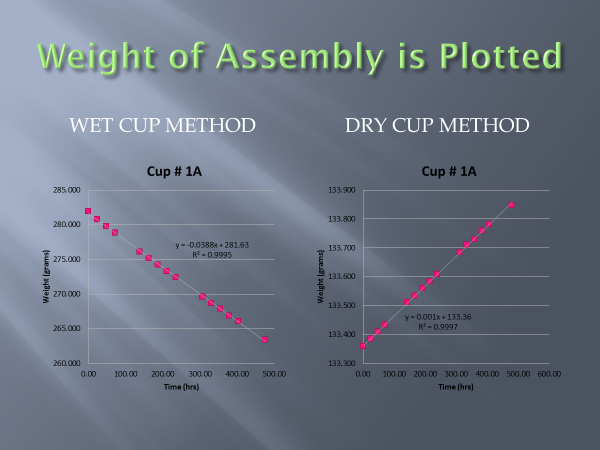

The weight data is plotted versus time. The system may at first gain or lose weight more quickly, and then settle into a constant or steady-state rate of weight change after a couple of days, or longer, depending on the type of material being tested.

The weight data is plotted versus time. The system may at first gain or lose weight more quickly, and then settle into a constant or steady-state rate of weight change after a couple of days, or longer, depending on the type of material being tested.

If the cup is filled with water, the dish loses water over the course of the test so the plot points downward. If the cup contains desiccant, the dish gains water (weight) over the course of the test, so the plot points upward. In either case, the slope of the plot is the rate of weight change and its units are mass per time. For example, the units might be grams per hour or nanograms per 24 hours.

What are the formulas and units for WVT, permeance, and permeability?

The WVT is determined by dividing the rate of weight change, which is the slope of the plot, by the area of the test specimen. The permeance and permeability may be calculated from the WVT.

What ASTM methods may be used to measure WVT?

ASTM E96 / E96M – 16, Standard Test Methods for Water Vapor Transmission of Materials

ASTM D1653 – 13, Standard Test Methods for Water Vapor Transmission of Organic Coating Films

ASTM D1653 and ASTM E96 both address the determination of the water vapor transmission and permeance of coatings. ASTM E96/E96M addresses the determination of permeability, but ASTM D1653 does not.

What are the differences between ASTM E96/E96M and ASTM D1653?

ASTM E96/E96M and ASTM D1653 differ in many ways. The scopes of the standards differ considerably. ASTM D1653 covers the evaluations of films of coatings: paint, varnish, lacquer, and other organic coatings. The films may be free films or they may be applied to porous substrates. ASTM E96 covers many materials, including coatings. It can be used to test paper, plastic films, other sheet materials, fiberboards, gypsum and plaster products, wood products, and plastics. ASTM D1653 includes directions for preparation of a free film, whereas ASTM E96 does not.

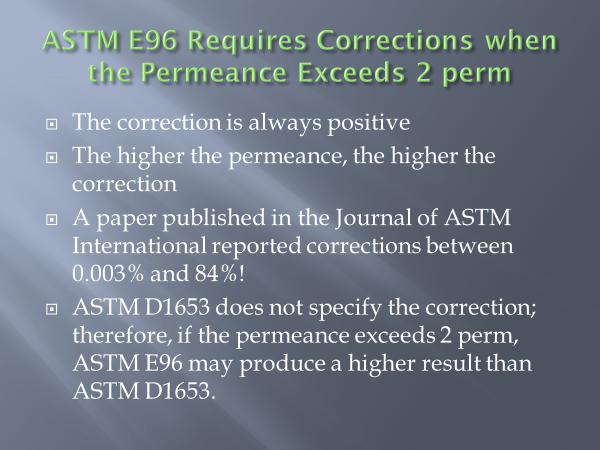

ASTM E96/E96M contains more specifications than does ASTM D1653—the former is several pages longer than the latter. For example, ASTM E96/E96M specifies a minimum dish size and the air velocity over the specimen; ASTM D1653 does not. A major difference between the two methods is that ASTM E96/E96M requires that permeance values exceeding 2 perm are corrected for something it calls Resistance due to Still Air and Specimen Surface. This correction can greatly change the results. In the example provided in ASTM E96/E96M, the correction increased the permeance from 46 perm to 66 perm. ASTM D1653 does not discuss this correction. See the slide below for more information about the correction.

What does the magnitude of the permeance indicate?

What does the magnitude of the permeance indicate?

Materials can be classified by the magnitude of their permeance as follows.

- Vapor Impermeable: less than 1 perm

- Vapor Semi-permeable: between 1 and 10 perms

- Vapor Permeable: greater than 10 perms

How precise is the testing? If a sample is tested twice by the dry cup method, and each test consists of three replicate trials, the difference between the permeance results from the two tests are expected to be less than a quarter of a perm if the permeance is less than 1 perm. That means two measurements of the same material with the dry cup method may differ by 25% or more for results less than 1 perm.

For the wet cup method, two results, each the mean of triplicate trials, are expected to differ by less than 74.2% relative at permeances between 5 and 30 perms. The repeatability statement for ASTM E96/E96M indicates its precision is no better. The repeatability values reported by these two ASTM standards indicate the permeance values determined are ball park figures.

What should one consider when comparing the permeance of coatings?

- Units: Verify that the units are the same

- Method: Wet Cup, Dry Cup, or Inverted Wet Cup

- Conditions: Temperature and Relative Humidity

- Testing Standard: ASTM D1653 or ASTM E96

- Coating Thickness: The permeance depends on the thickness of the coating

It is best to only compare permeance values measured according to the same ASTM standard, (ASTM E96/E96M or D1653), and the same method, (wet cup method or dry cup method), and at the same air temperature and humidity. Be cautious when comparing results obtained using different test methods because results reported per ASTM E96/E96M may have been corrected, whereas results reported per ASTM D1653 have not been. Finally, be cautious when comparing the results obtained by the dry cup method to the wet cup methods. The wet cup method can produce higher results than the dry cup method when the same coating is tested under the same air temperature and humidity conditions.