The Issue

There are two questions that can arise when performing in-process quality checks of surface preparation and coating application processes, or when evaluating the performance of a coating system already in service. These include, “How do I perform the tests,” and “What is the frequency required to ensure my test data is representative?” The answer to the first question (“How?”) is commonly answered by sourcing the appropriate ASTM standard test methods, or by referencing SSPC: The Society for Protective Coatings or NACE International standards. Training to become proficient in performing these tests is also an important consideration. But the answer to the second question (“frequency” or “how often?”) may or may not be addressed by industry standard test methods. Let’s look at a few examples.

Use of the Terminology “Area” and “Location”

As you’ll see in the information provided below, standards often refer to the number of tests to perform in each “area” but oftentimes mean “test location.” The dimensions of an “area” are, for the most part undefined (there are noted exceptions below). An area may be a small section of a structure, or the entire structure. Test location is more descriptive and better represents what is meant when referring to testing frequency.

Examples of Coatings Industry Standards That Address Frequency of Measurement

ASTM D7091, Standard Practice for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to Ferrous Metals and Nonmagnetic, Nonconductive Coatings Applied to Non-Ferrous Metals describes three operational steps necessary to ensure accurate coating thickness measurement, as well as proper methods for obtaining coating thickness measurements on both ferrous and non-ferrous metal substrates. The standard states that coating thickness can vary widely across a surface, and that obtaining single-point measurements may not accurately represent the actual coating system thickness. It references SSPC-PA 2 (described below) for frequency of thickness measurements and the acceptability of those measurements.

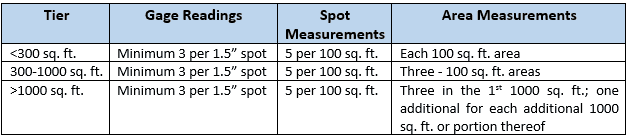

SSPC-PA 2, Procedure for Determining Conformance to Dry Coating Thickness Requirements describes a procedure for determining shop or field conformance to a specified coating thickness range on ferrous and non-ferrous metal substrates using nondestructive coating thickness gages (magnetic and eddy current) described in ASTM D7091. Section 8 in the SSPC-PA 2 standard prescribes the number of gage readings, spot measurements and area measurements to obtain based on the size of the coated area (e.g., the area coated during the previous shift that is ready for inspection). The chart below summarizes the frequency of tests prescribed in the standard.

Another example where the frequency of measurement is addressed by industry standards includes two of the three methods of measurement described in ASTM D4417, Standard Test Methods for Field Measurement of Surface Profile of Blast Cleaned Steel and SSPC-PA 17, Procedure for Determining Conformance to Steel Profile/Surface Roughness/Peak Count Requirements. Depending on the method of measurement, the number of readings to take per location is described in ASTM D4417 (e.g., Method B [depth micrometer] is 10, and Method C [replica tape] is 2), while SSPC-PA 17 addresses the number of locations to measure (minimum of three 6” x 6” areas), based on the area prepared in a work shift or 12-hour period, whichever is shorter.

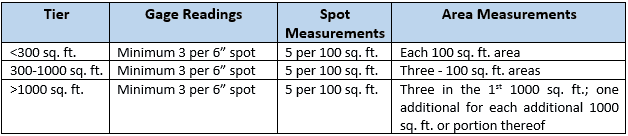

One final example where the frequency of measurement is addressed by industry standards is ASTM D6132, Standard Test Method for Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using an Ultrasonic Coating Thickness Gage, which describes the operational steps necessary to ensure accurate coating thickness measurement, as well as proper methods for obtaining coating thickness measurements on non-ferrous substrates like concrete using ultrasonic principles. The ASTM standard does not address frequency of measurements, so SSPC published a complimentary standard known as SSPC-PA 9, Measurement of Dry Coating Thickness on Cementitious Substrates Using Ultrasonic Gages that provides a frequency of measurement, which is summarized in the table below.

So in the case of coating thickness (applied to metal and concrete) and surface profile, the frequency of measurement acquisition is described in industry standards and can be applied as long as the standard(s) is invoked by the specification.

Examples of Coatings Industry Standards That

Do Not Address Frequency of Measurement (but probably should!)

Section 7.1.4 of ASTM D4417 addresses the measurement of surface profile using a visual comparator (Method A) and instructs the user to evaluate the roughness… “at a sufficient number of locations” to characterize the surface after abrasive blast cleaning is performed. The term “sufficient” is relative, and may mean one or two test locations to one person, and 15 or 20 locations for another, so it is important to specify the number of locations or obtain agreement between the interested parties beforehand.

ASTM D4541, Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion

Testers states that, “At least three replications are usually required in order to statistically characterize the test area (i.e., location);” however it does not indicate how many test locations to select, in order to characterize the adhesion properties of the coating system on the entire structure.

Similarly, ASTM D3359, Standard Test Methods for Measuring Adhesion by Tape Test states, “for large structures make sufficient tests to ensure that the adhesion evaluation is representative of the whole surface.”

Therefore, for adhesion testing (tensile or shear), it is important to establish a test frequency upfront. Considerations may include the number of heterogeneous areas on a given structure, variations in coating thickness, etc. A statistically significant sampling may or may not be feasible, given that these tests are destructive to the coating film and each area of test may need to be repaired. Other considerations include whether adhesion testing is part of a quality assessment (where destructive testing should be minimized), or if it is being employed to help diagnose the cause of a coating failure, where additional destructive tests have little negative impact, but can provide value in examining a problem.

Suggested Approach for Developing a Frequency of Measurement

There is no panacea for solving the frequency of measurement issue. Recognizing that it isn’t practical to perform 100% testing of every square foot of a surface, what is considered to be reasonable sampling? One approach is to discuss the issue with all stakeholders and agree on an approach that appears reasonable, and hopefully common sense will prevail. It may be a tiered approach; e.g., test at a greater frequency early in the cleaning/painting sequence, and analyze the data. If the deviation is relatively minor, perform less frequent testing. It may yield the same result, yet be much more efficient. However, if there is a high degree of variation in data points, then more frequent testing may be warranted.

ASTM E122, Standard Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or Process appears to have applicability for those standards that do not invoke a frequency of measurement. The Practice is intended for use in determining the sample size required to estimate, with specified precision, a measure of quality of a lot or process either as an average value or as a fraction not conforming to a specified value. The practice applies when quality is expressed as either the lot average for a given property, or as the lot fraction not conforming to prescribed standards. There are multiple equations and a few applications for each described in this Standard Practice, so applicability and subsequent selection of the correct equation is important when using this approach.

Hi, Bill,

I am Giuseppe Santagata from Italy and I am a certified NACE inspector since ’92. I would like to underline that on my point of view regarding the DFT readings, location etc. that to be honest SSPC-PA2, ISO 19840, or 2808, AS, IMO rules, etc. are not representative as well for large and complex structures like Modules, Bridges, Decks, etc. I prefer ask to the inspectors an accurate visual inspection of the coated surfaces to be verified without consider any standard, and make a certain number of readings that their retain be representative for the area under exam and to dedicate more attention on areas where the coat is difficulty to be applied by means of spray technique, striping coat, etc. . The rules, standard, etc. are a good points to be adopted only in case of dispute between parties. Defining in this scenario, before to commence any verification the standard to be utilized, acceptance criteria, etc. I apologize for my bad English.

Giuseppe,

Thank you for your commentary regarding the article posted to KTA University addressing the frequency of measurements. I agree wholeheartedly. A good inspector will spot check difficult access areas and areas that visually appear deficient, independent of the frequencies set-forth by the standards. This “common sense” approach to coatings inspection can’t be written into a standard but is nonetheless valuable. There is always a concern of “over-inspection” by taking so many measurements that production is impeded. Also note that the Quality Control Inspector (working for the contractor) is responsible measuring according to the standards; Quality Assurance Inspectors (working for the facility owner) do more spot checking and verifying uniform coverage/consistency (related to DFT measurement).

-William D. Corbett