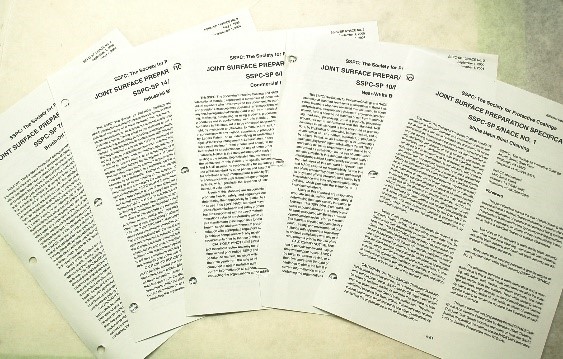

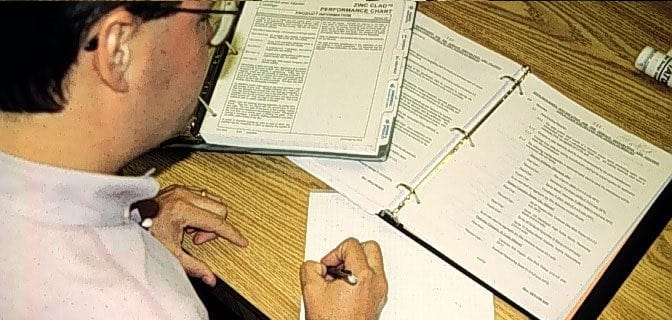

The Importance of Preparing Jobsite Standards for Surface Cleanliness and Surface Profile Depth Prior to Production Operations

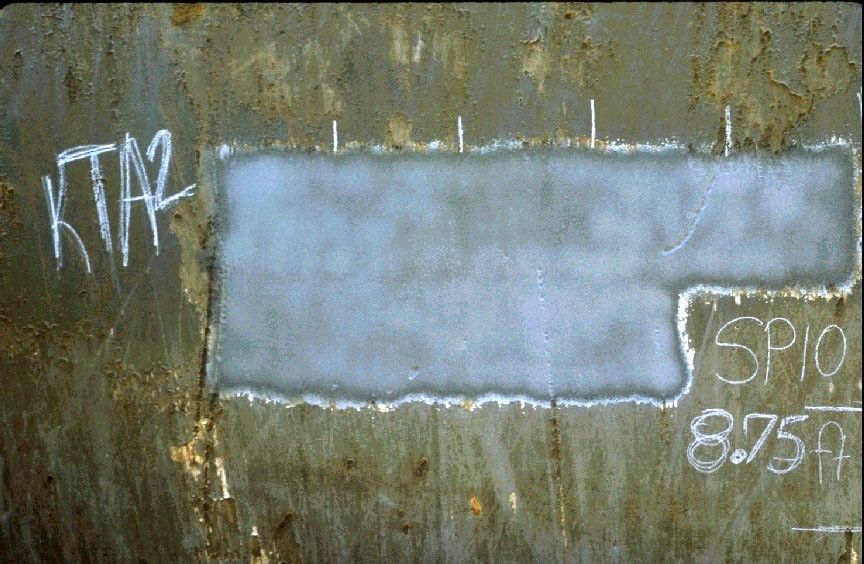

Introduction Surface preparation prior to coating installation is generally composed of two goals: achieving the minimum specified surface cleanliness, and achieving the specified range of surface profile (surface roughness). While these goals may be achieved in a single operation (e.g., by abrasive blast cleaning) or two separate operations (e.g., by water jetting or chemical stripping, […]