Laboratory Methods for Simulating Various Service Environments by Immersion Testing

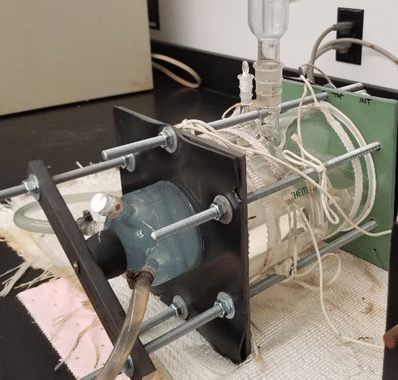

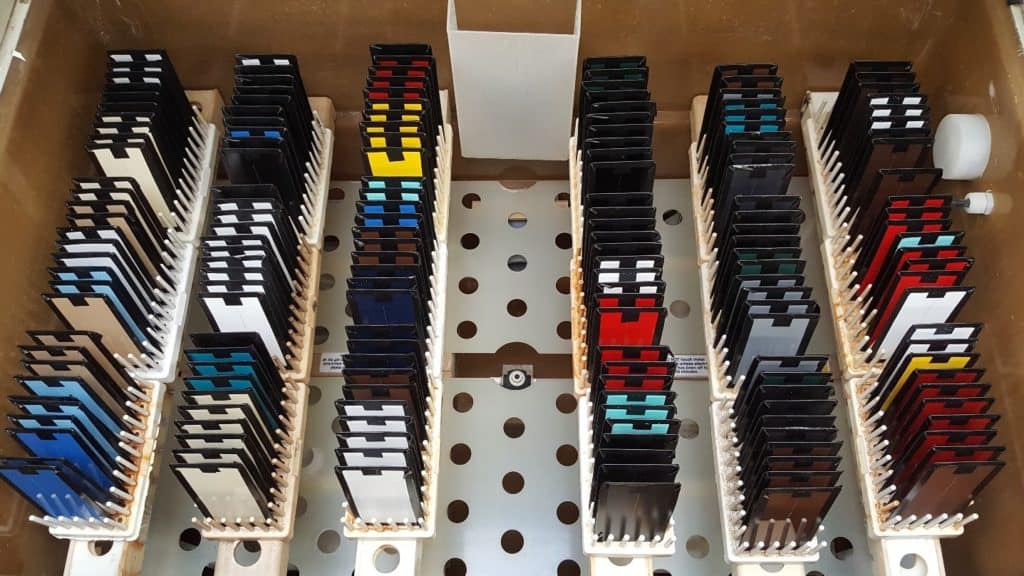

IntroductionThere are a wide range of immersion environments where protective coatings (liquid or powder), sheet materials, or rubber linings may be expected to protect an asset. Some of the environments range from basic water immersion to chemical immersion with perhaps high pressure and elevated temperatures. The most widely protected assets are constructed of concrete and […]

Laboratory Methods for Simulating Various Service Environments by Immersion Testing Read More »