Defining and Assessing the Texture of Concrete Floor Coatings

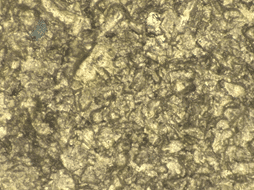

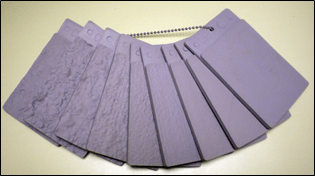

Concrete floor coating systems are frequently specified to be textured to improve traction. The surface texture, however, is only one variable that affects the slip resistance of a surface. Slipping can arise from a failure of traction on the interface between, for example, the footwear and the walking surface and is affected by the floor […]

Defining and Assessing the Texture of Concrete Floor Coatings Read More »